Copyright Interesting Engineering

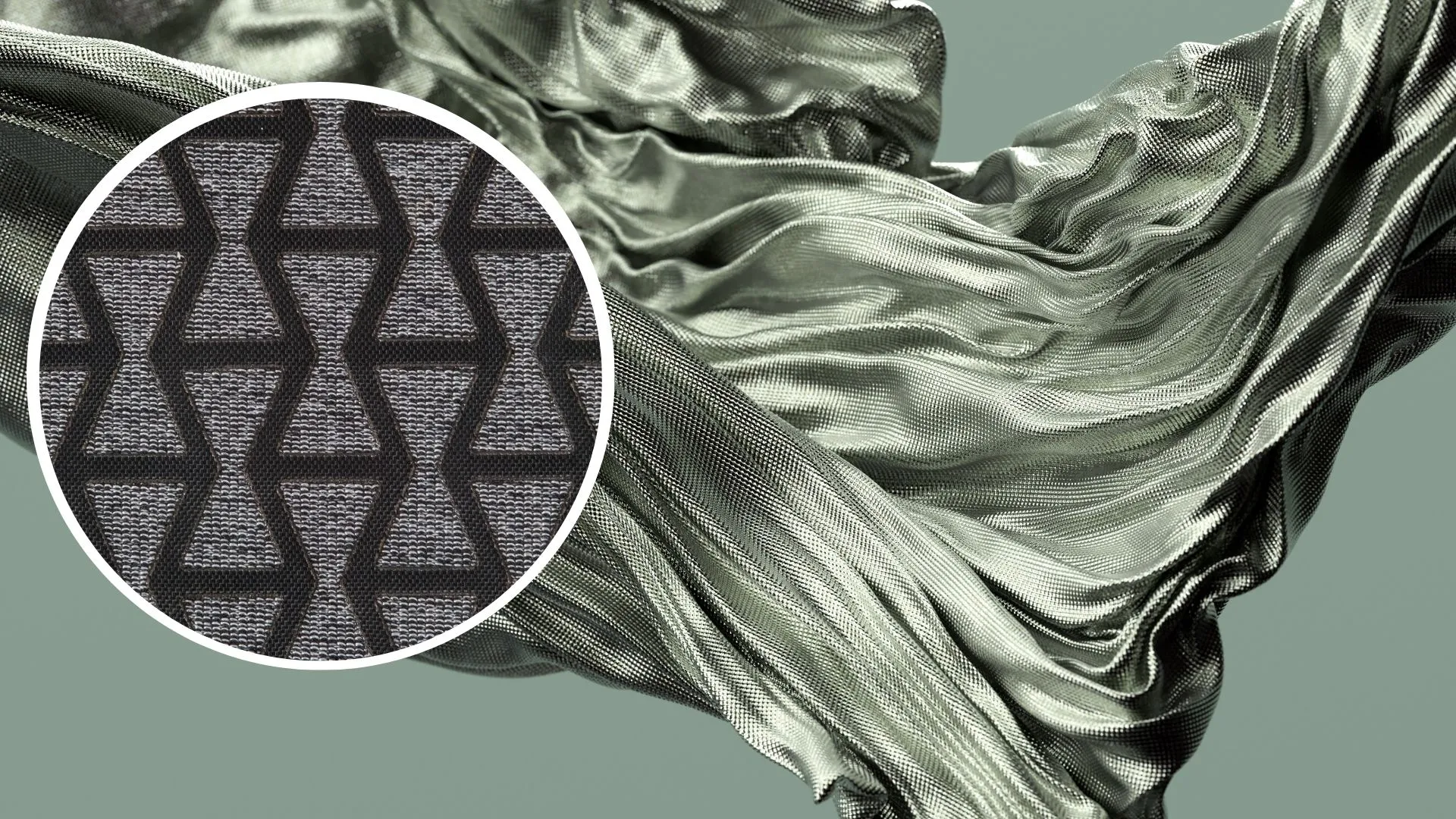

Researchers have developed a new type of textile that can adjust its aerodynamic properties while worn on the body. Developed by researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), the innovation has the potential to change not only high-speed sports, but also industries like aerospace, maritime, and civil engineering. The research team revealed that the new type of textile uses dimpling to adjust its aerodynamic properties. Innovation can change industries like aerospace, maritime, and civil engineering The innovation is claimed to have the potential to change not only high-speed sports, but also industries like aerospace, maritime, and civil engineering. “By performing 3,000 simulations, we were able to explore thousands of dimpling patterns,” said SEAS mechanical engineering graduate student David Farrel. “We were able to tune how big the dimple is, as well as its form. When we put these patterns back in the wind tunnel, we find that certain patterns and dimples are optimized for specific wind-speed regions.” Unique textile forms dimples on its surface when stretched The unique textile forms dimples on its surface when stretched, even when tightly fitted around a person’s body. The fabrics utilize the same aerodynamic principles as a golf ball, whose dimpled surface causes a ball to fly further by using turbulence to reduce drag. Because the fabric is soft and elastic, it can move and stretch to change the size and shape of the dimples on demand. The research team also underlined that adjusting dimple sizes can make the fabric perform better in certain wind speeds by reducing drag by up to 20%, according to the researchers’ experiments using a wind tunnel. Researchers used a laser cutter and heat press to create a dual-toned fabric made of a stiffer black woven material, similar to a backpack strap, and a gray, softer knit that’s flexible and comfortable. Using a two-step manufacturing process, they cut patterns into the woven fabric and sealed it together with the knit layer to form a textile composite. Experimenting with multiple flat samples patterned in lattices like squares and hexagons, they systematically explored how different tessellations affect the mechanical response of each textile material, according to a press release. Textile composite’s on-demand dimpling The textile composite’s on-demand dimpling is the result of a lattice pattern. Stretch a traditional textile onto the body, and it will smooth out and tighten. While this textile breaks the rule and its unique lattice pattern allows the textile to expand around the arm rather than clamp down, according to researchers. Published in Advanced Materials, the paper reveals that the textile metamaterial is introduced that is capable of variable aerodynamic profiles through a stretch-induced dimpling mechanism, even when tightly conformed to a body or object. “Wind-tunnel experiments are used to characterize the variable aerodynamic performance of the dimpling mechanism, while Finite Element (FE) simulations efficiently characterize the design space to identify optimal textile metamaterial architectures,” said researchers in the study. “By controlling dimple size, the aerodynamic performance of the textile can be tailored for specific wind-speed ranges, resulting in an ability to modulate drag force at target wind-speeds by up to 20%.”