Copyright Interesting Engineering

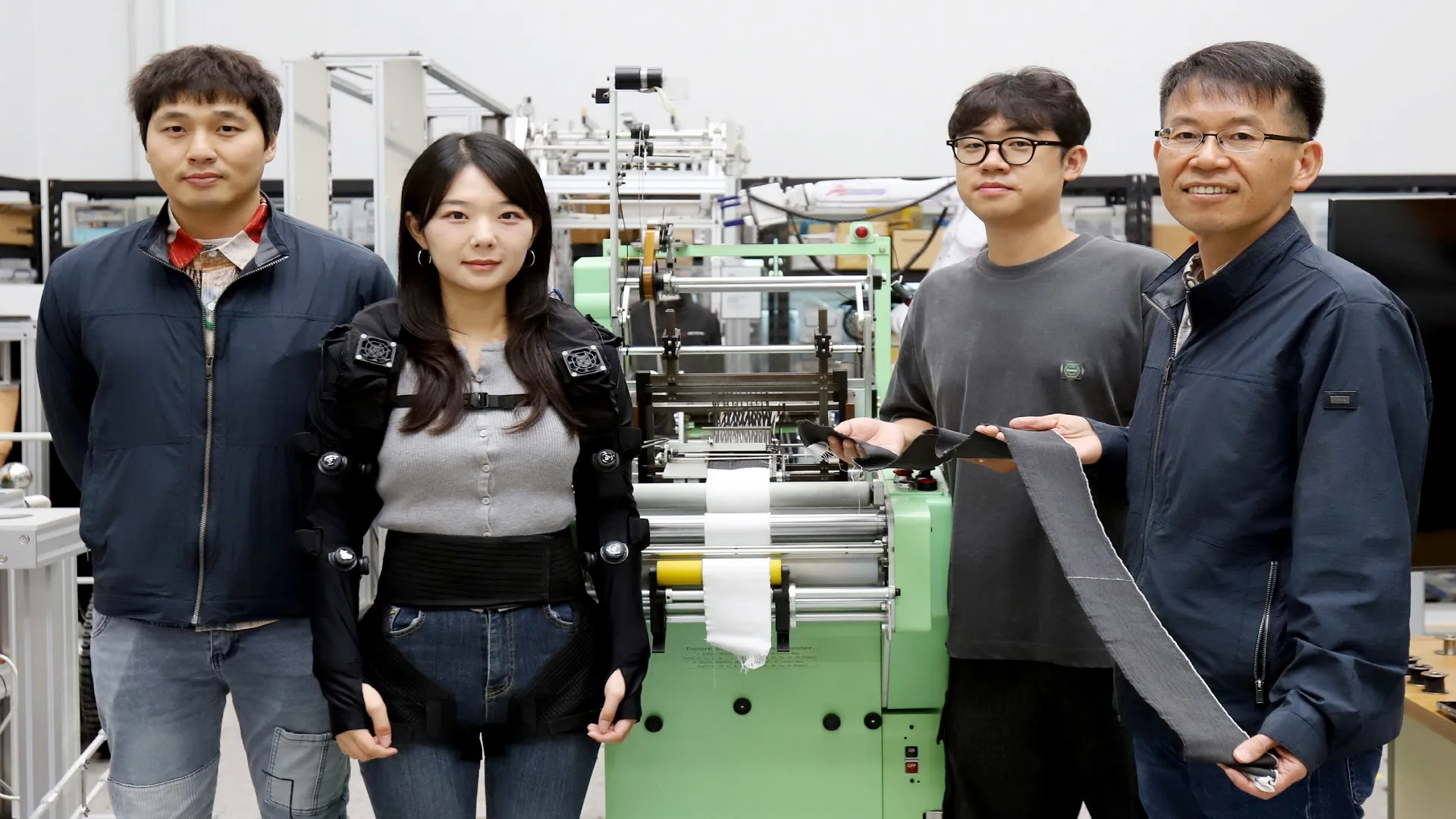

A new breakthrough from South Korea could soon make wearable robots feel as natural as clothing. Researchers from the Advanced Robotics Research Center at the Korea Institute of Machinery and Materials (KIMM) have built an automated weaving system that continuously produces ultra-thin, shape memory alloy coil yarn, thinner than a human hair. This breakthrough allows large-scale production of lightweight, flexible artificial muscles for next-generation wearable robots. Led by Principal Researcher Cheol Hoon Park, the team’s system uses 25-micrometer-wide shape memory alloy (SMA) wire processed into coil-shaped yarn to create fabric muscles that can lift 10 to 15 kilograms while weighing just 10 grams. This is a key advancement in the long quest to make wearable robots practical for everyday use. Traditional systems rely on bulky, noisy motors or pneumatic actuators that restrict motion and are uncomfortable for extended wear. KIMM’s fabric muscle, by contrast, mimics the structure and flexibility of human tissue, allowing wearable robots to move more naturally and assist multiple joints simultaneously. To achieve continuous production, the researchers replaced the metallic core in earlier SMA coils with natural fiber and redesigned both the weaving machine and the actuator’s structure. The result is a stable, automated process that allows for uniform, high-quality output, an essential step toward commercialization. Strength woven in threads Using this fabric muscle technology, the KIMM team created the world’s first clothing-type wearable robot weighing under two kilograms. The system can assist the elbow, shoulder, and waist at the same time, reducing muscle effort by over 40 percent during repetitive tasks. They also developed an ultra-light shoulder-assist robot weighing only 840 grams, designed for people with muscular weakness. In clinical trials at Seoul National University Hospital, the wearable robot improved shoulder movement range by more than 57 percent among patients with Duchenne muscular dystrophy and other neuromuscular disorders. Beyond rehabilitation, such wearable robots could soon find applications in manufacturing, logistics, and healthcare, where they could help workers and patients perform physically demanding tasks more safely. From lab to life The ability to mass-produce fabric muscles marks a turning point for wearable robotics. By combining flexibility with high strength, these actuators can be integrated into lightweight garments that move seamlessly with the body. “Our development of continuous mass-production technology for fabric muscle—the key component of clothing-type wearable robots—will significantly improve quality of life in fields such as healthcare, logistics, and construction,” said Dr. Cheol Hoon Park. “We will continue to build on KIMM’s extensive wearable robotics technologies to accelerate commercialization and lead the global wearable robotics market.” The research, which received the KIMM Best Research Award 2024, was supported by the institute’s ACE program and Korea’s Core Robot Technology Development Program under the Ministry of Trade, Industry and Resources, as well as the Lee Kun-hee Child Cancer and Rare Disease Project at Seoul National University Hospital. The findings were published in IEEE Transactions on Neural Systems and Rehabilitation Engineering (TNSRE).