Copyright scmp

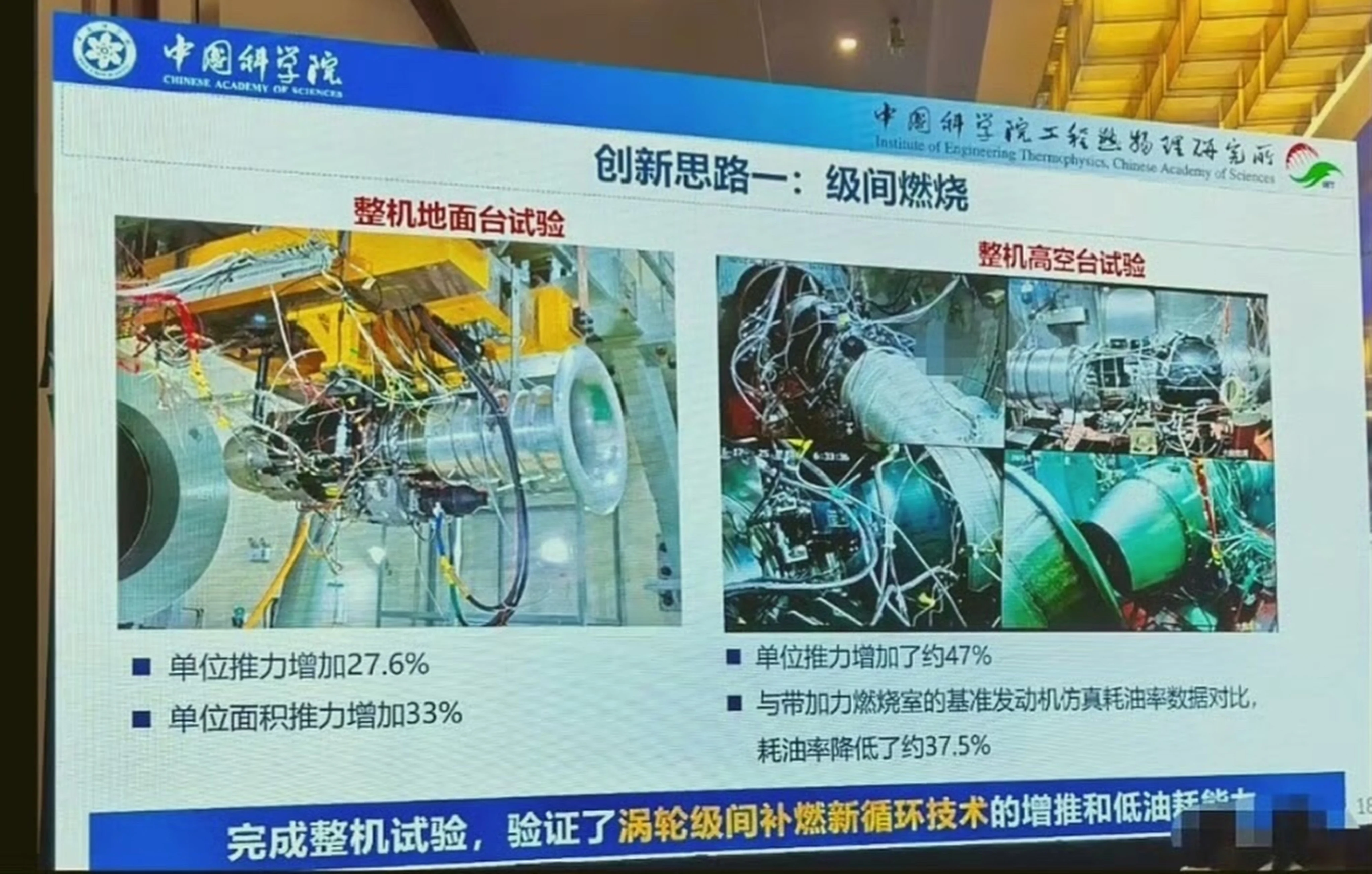

China has completed ground and altitude tests of an adaptive cycle engine prototype with unprecedented thrust, efficiency and speed range, according to presentations at the Chinese Society of Engineering Thermophysics annual conference in Beijing last week. During the opening day report, Xu Gang, deputy director of the Institute of Engineering Thermophysics at the Chinese Academy of Sciences, presented his team’s research progress in adaptive cycle engine (ACE) technology. This advanced engine is poised to become the ideal power plant for next-generation fighter aircraft and future supersonic civilian transport, challenging a field long dominated by the United States. Xu said in his report summary that his institute had pioneered “bypass combustion and inter-stage mixing variable-mode engine” technology. This breakthrough overcomes the severe thrust attenuation of traditional turbine engines at high altitudes and speeds. The engine can achieve supersonic cruise at high Mach numbers and also serve as the high-speed turbine component for combined-cycle propulsion systems, resolving the “thrust trap” issue in such systems. Notably, the competing US approach uses a dual-bypass architecture, while the Chinese system features a novel three-stream design. The key characteristic of this third stream is its lower-temperature airflow, which can be used to extract more power, achieve superior thermal management, reduce installation drag, improve inlet pressure recovery, lower exhaust temperature, and diminish infrared signature. The engine operates in two distinct modes: Mode 1, with the main combustor active for subsonic cruise, and Mode 2, with the bypass combustor engaged for supersonic cruise. According to data from Xu’s presentation, ground tests showed a 27.6 per cent increase in specific thrust, while high-altitude tests demonstrated a 47 per cent increase. And compared to a baseline engine, fuel consumption was reduced by 37.5 per cent. Analysis of a chart displaying the relationship between Mach number and corrected airflow indicated that this engine can operate at speeds of up to Mach 4. Xu has long been engaged in fundamental technology research for light turbine-based aviation propulsion systems, combustion and overall engine design. He has been the chief engineer for multiple turbojet and turbofan engine programmes. His work has broken through several technological barriers, leading to the development and application of multiple cost-effective, high-performance light aero-engines. The core challenge of aero-engine advancement is in simultaneously increasing thrust and improving fuel efficiency – two objectives often at odds with each other. A conventional turbojet engine operates sequentially: air enters through the intake, is compressed, mixed with fuel, ignited in the combustion chamber, drives the turbine, and is finally expelled through the nozzle to produce thrust. During low-speed flight, air flows smoothly into the engine. However, as speed increases, air effectively “rams” into the compressor, disrupting its operation. This leads to a lack of airflow, resulting in a drop in thrust – a major performance limitation. The variable cycle engine (VCE) was conceived to overcome this problem. It later evolved into the more advanced ACE. A VCE employs adjustable baffles and internal pathways to modulate thermodynamic cycle parameters like pressure ratio, airflow and bypass ratio. This allows the engine to maintain high performance across diverse flight conditions. The ACE is a conceptual evolution of the VCE that can seamlessly transition between a high-thrust mode and a high-efficiency mode. For fuel-efficient cruising, the engine increases its bypass ratio, channelling more air through the external duct. This configuration is ideal for subsonic flight, offering low noise and reduced fuel consumption. When greater thrust is required for acceleration or supersonic flight, the engine reduces the bypass ratio, directing more air into the core. While the principle is straightforward, its engineering implementation is exceptionally challenging. Any mechanical adjustment within the high-temperature, high-pressure, high-stress environment of a running engine risks structural damage and safety hazards. Even with a flawless design, the material requirements are demanding. The concept of the VCE dates back to the 1960s with the US giant General Electric (GE). After decades of exploration and development, GE’s YF120 engine, designed in 1990, successfully completed test flights on both the YF-22 and YF-23 fighter prototypes. Although the YF120 ultimately lost the F-22 engine competition to Pratt & Whitney’s YF119, its technology and potential were widely acknowledged. In 2005, the US launched the Commercial Supersonic Technology (CST) programme to maintain its leadership in global aviation. Building on prior experience, GE proposed an early ACE concept under this initiative. In 2016, the US Air Force initiated the Adaptive Engine Transition Programme (AETP) to develop ACE engineering prototypes for a potential engine upgrade for the F-35 fighter. Both GE and Pratt & Whitney received contracts to produce demonstrator engines, the XA100 and XA101, respectively. Both have now progressed to the full-engine testing phase. However, facing budget constraints, the US Congress formally confirmed in its 2024 budget that the F-35 engine upgrade would proceed with the F135 Engine Core Upgrade (ECU), effectively delaying the military deployment of ACE technology. Han Yuqi, a senior engineer at the China Aero Engine Academy, noted in an August article for the journal Aerospace Power that compared to the F135, equipping the F-35A with the XA100 could improve fuel efficiency by 25 per cent, increase range by 30 per cent, boost thrust by 10 per cent and double heat management capacity.