Copyright Interesting Engineering

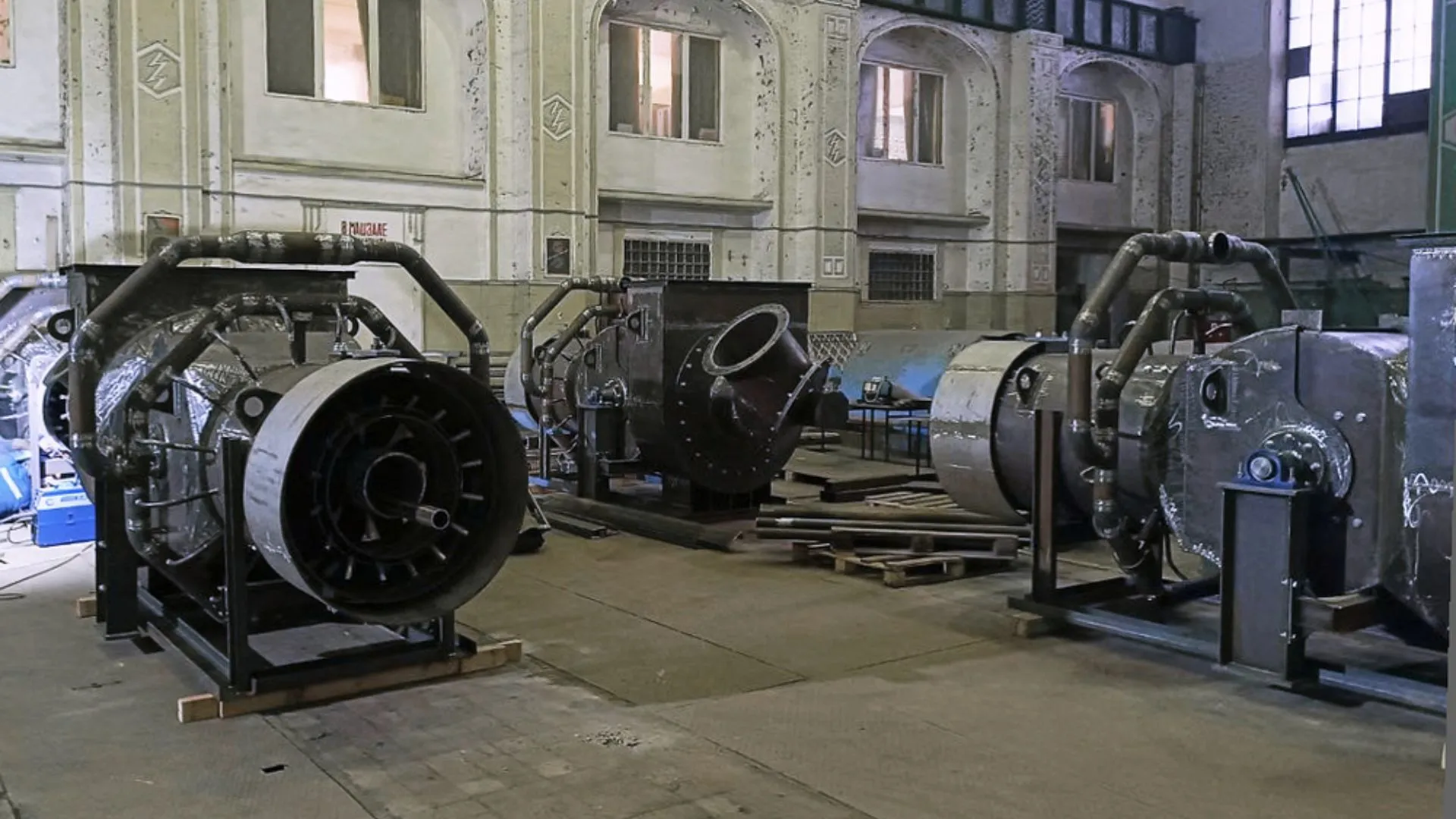

A Russian thermal engineering institute has successfully tested the world’s first pulverized coal burner with a variable flame vector. The new type of vortex burner can adjust the flame direction along the height of the combustion chamber. Developed by specialists from the steam generator and combustion equipment department at JSC VTI, the new solution is claimed to help reduce the process’s negative impact on the atmosphere, improve economic efficiency, and strengthen the technological independence of the domestic energy sector. New pulverized coal burner design This development is the first to be implemented at an industrial power unit and is unique in the global energy sector. The team claimed that the new pulverized coal burner design allows for vertical and horizontal flame direction adjustment, thereby adapting the combustion mode to the specific fuel’s characteristics and the current boiler operating parameters. A pulverized coal burner is a mechanical device that burns coal ground into a fine powder, or “pulverized coal,” for high-temperature industrial heating. An additional benefit of this design is the ability to reduce nitrogen oxide formation by optimizing the distribution of oxidizer and fuel along the flame. This solution is innovative in global energy practice and is the first to be implemented in an industrial power unit, according to a press release. New possibilities for solid fuel-fired power plants “The VTI development opens up new possibilities for solid fuel-fired power plants. The ability to adjust the flare direction provides flexibility when switching between different coal grades, reduces the risk of slagging, and helps maintain optimal steam parameters,” noted specialists from the Steam Generators and Furnace Equipment Department at VTI JSC. The team highlighted that the development underwent pilot testing at Tomsk State District Power Plant-2, a branch of Tomsk Generation JSC. The tests were conducted under various loads and combustion conditions, allowing for an assessment of the impact of flame position on the boiler’s thermal performance and heating surface operation. The specialists also claimed that the technology can be utilized in both the modernization of existing power units and the design of new boiler systems. Variable flame vector stabilizes the superheated steam temperature Generally, a pulverized coal burner that burns coal ground into a fine powder operates by injecting pulverized coal with primary air into a combustion chamber, where it is mixed with secondary air to create a turbulent, high-efficiency flame suitable for applications such as kilns and boilers. During a year of trial operation, VTI specialists observed the stable operation of the rotary elements at high temperatures, the absence of jamming, and the consistent performance of the device. Testing confirmed the reliability of the mechanical components and the effectiveness of the control system, as per the release. The team also underlined that traditional burners are designed to burn a single, designated fuel type. However, in today’s environment, the Russian thermal power industry is faced with the need to switch to different types of coal, each with a different ash content and calorific value. The institute’s new development addresses this challenge: a variable flame vector stabilizes the superheated steam temperature, regulates the heat absorption in the combustion chamber, and ensures a uniform temperature distribution, thereby improving boiler reliability and efficiency.