Copyright Interesting Engineering

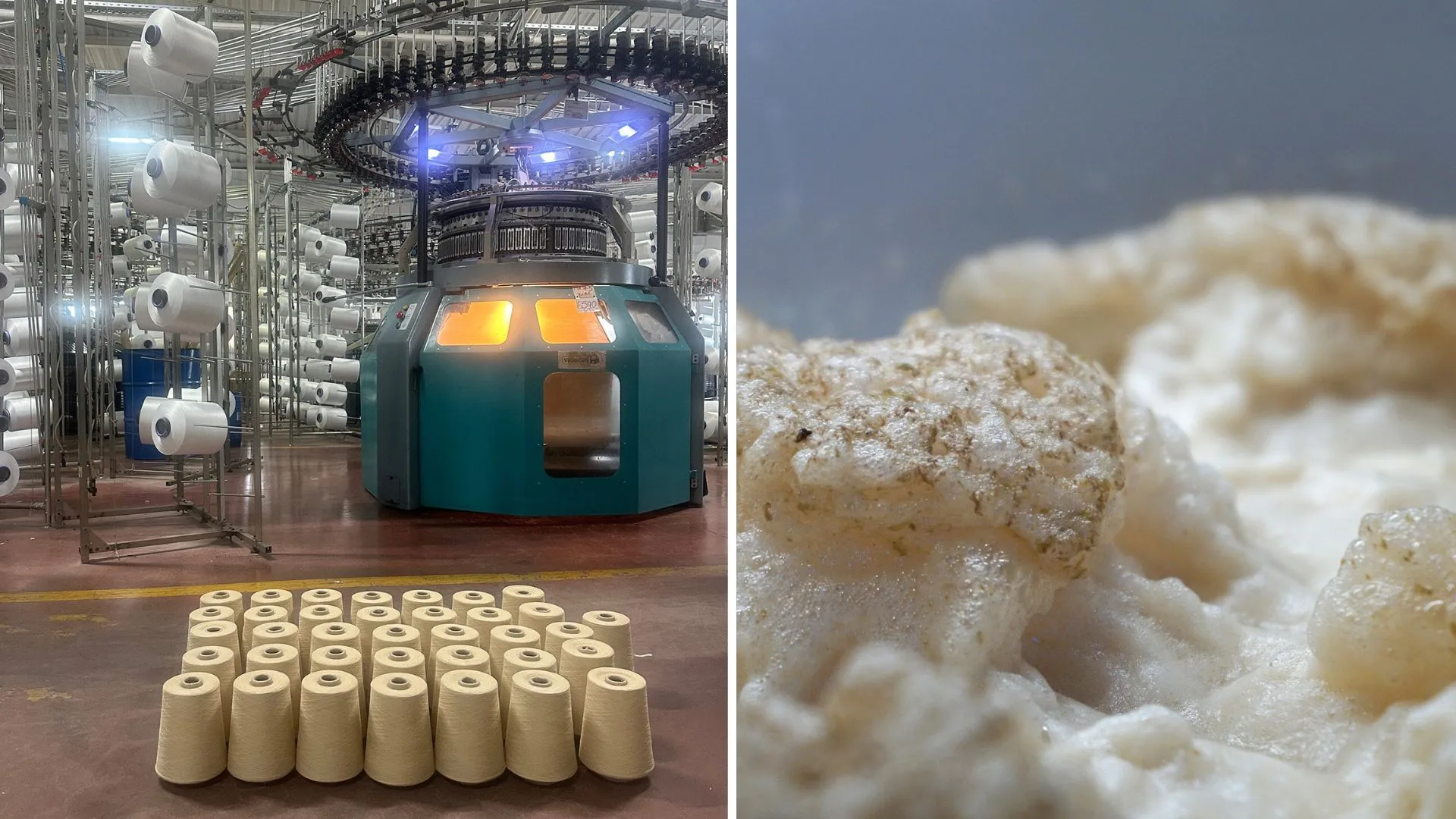

Strong clothing fiber can be manufactured from the waste yeast left over after producing beer, wine, or pharmaceuticals, a new study suggests. Composed of elements like proteins, fatty lipids, and sugars, the yeast biomass remaining after alcohol and drug production is typically classified as a byproduct or waste. Researchers at Pennsylvania State University in the US have developed a sustainable, protein-based fiber from this waste material. The resulting fiber is reported to be stronger than natural fibers and can be produced for $6 or less per kilogram (compared to $10-$12 for wool). Interestingly, it could potentially address both world hunger and the environmental impact of fast fashion. Protein-based fiber The idea of using proteins to create fiber isn’t new, but past attempts failed to compete with synthetic materials. For instance, Lanital, a material developed in the 1930s from milk protein, fell out of favor because of its low strength when polyester emerged. Ultimately, early bio-based fibers (like those from peanut and corn proteins) couldn’t overcome the dual challenges of poor performance and high cost, letting cheap, strong polyester take over the market. In this new study, proteins were extracted from the yeast, dissolved in a solvent, and forced through a spinneret to create continuous fibers, which were then spun into yarn. The successful pilot-scale production of the fiber was achieved in a German factory, resulting in over 1,000 pounds of material. It involved both continuous and batch production runs, each lasting more than 100 hours of fiber spinning. This durable, protein-based fiber prevents the release of persistent, harmful chemicals into the environment. In contrast to polluting polyester, these fibers are biodegradable and will naturally decompose after disposal. Sustainable option for land use A commercial-scale assessment revealed that the fermentation-based fiber is economically viable and can compete with wool and other fibers. The study showed the fiber‘s strong commercial potential, based on simulations using pilot data. The analysis suggests that the massive land, water, and energy currently dedicated to growing fibers like cotton could be repurposed for food production. Currently, the environmental cost of traditional cotton is high, as producing just a single T-shirt and a pair of jeans requires up to 2,642 gallons of water. Furthermore, cotton uses roughly 88 million acres of global farmland, including land in food-insecure regions such as India. The problem of global food insecurity — affecting 733 million people in 2023, prompting the UN’s Zero Hunger goal — could be partially solved by adopting this new fiber. “We successfully demonstrated that this material can be made cheaply—with significantly less water and land but improved performance compared to any other natural or processed fibers, while also nearly eliminating greenhouse gas emissions,” said Melik Demirel, lead author and Pearce Professor of Engineering and Huck Chair in Biomimetic Materials at Penn State. Furthermore, the current production methods contribute to a huge waste problem, with over 66% of US clothing ending up in landfills annually. The new approach offers a dual solution that simultaneously conserves agricultural resources and produces a biodegradable alternative to address landfill waste. The research team plans to investigate the commercial-scale viability of fermentation-based fibers further and bring the product to the mass market. The findings were published in the journal Proceedings of the National Academy of Sciences on November 3.