Copyright Interesting Engineering

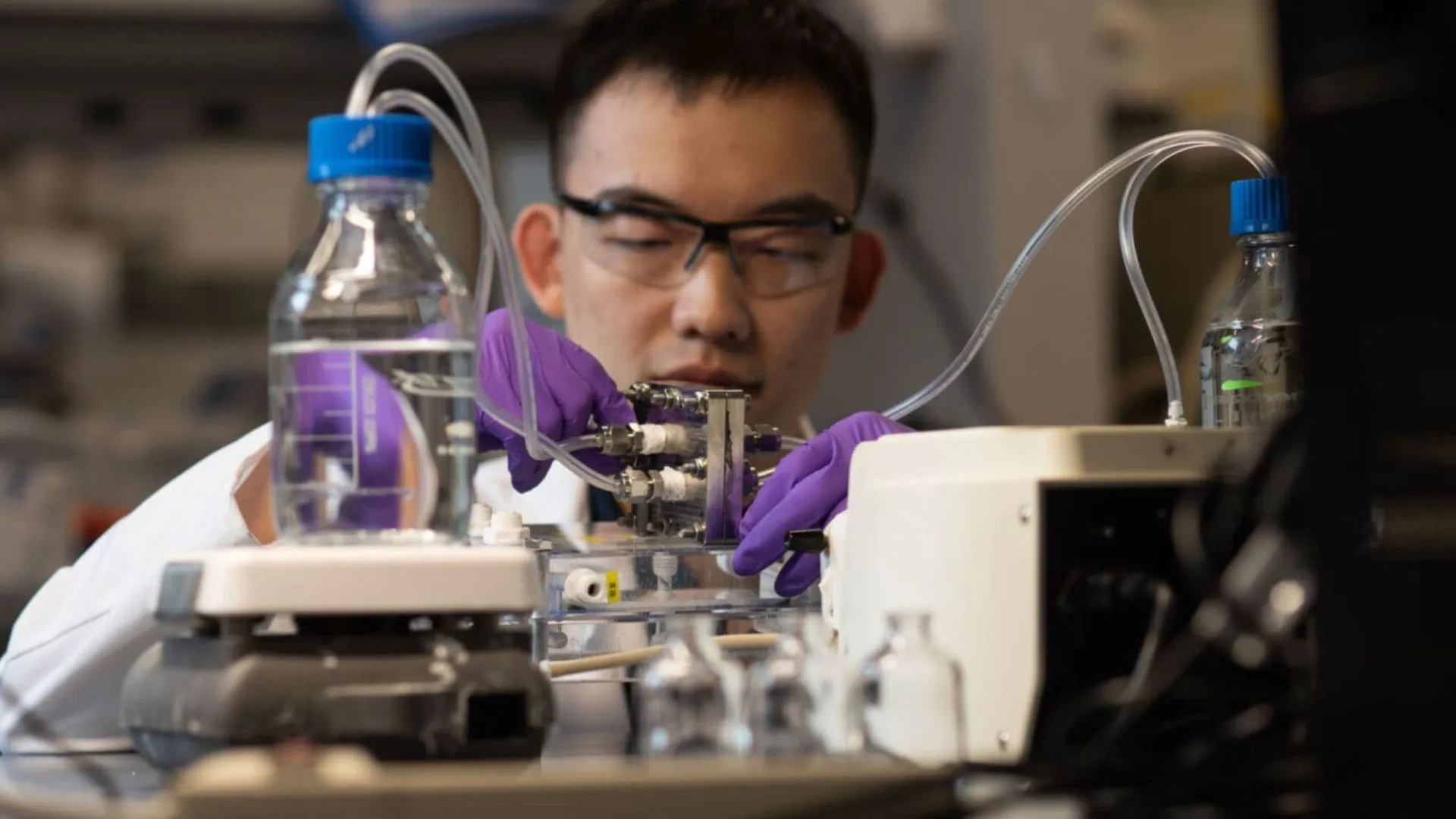

The Princeton team has identified a way to use reclaimed wastewater instead of ultrapure water to produce green hydrogen via electrolysis. This change reduces the high cost and environmental stress of the clean water needed in hydrogen fuel production. “Hydrogen infrastructure generally competes with local fresh water use,” said Z. Jason Ren, the senior study author, on October 28. “But every town has a wastewater treatment plant, and that’s a very distributed source of water for the hydrogen economy,” added Ren, who is a professor of civil and environmental engineering. Solving existing wastewater use problem Green hydrogen is produced by using renewable electricity to split water into hydrogen and oxygen via electrolysis. It offers much lower carbon emissions than other methods. However, this process typically requires costly ultrapure water to prevent impurities from damaging the specialized membrane within the electrolyzer. The researchers worked to bypass the costly water purification process for green hydrogen. For this sustainable method, “reclaimed wastewater” was tested instead of tap water. Reclaimed wastewater is treated water suitable for discharge or non-drinking uses like irrigation or industrial cooling. This method had been attempted before, but those efforts to use wastewater as a source quickly failed. To address the problem, the team first analyzed why the system failed in a standard commercial electrolyzer, which then informed the design of their new solution. The experiment utilized a proton exchange membrane water electrolyzer, which is the standard commercial technology currently employed with ultrapure water. It was found that the previous attempts failed due to calcium and magnesium ions (common minerals causing scale) in the wastewater sticking to the proton exchange membrane in the electrolyzer. This blocked ion transport and caused a rapid performance decline. Reduces energy need The Princeton team solved this by acidifying the reclaimed wastewater with sulfuric acid. This buffer serves as a rich source of protons that outcompete the problematic calcium and magnesium ions. The step successfully maintains ion conductivity across the membrane, sustains the necessary electrical current, and ultimately enables continuous hydrogen production without system failure. “It’s expensive to remove all those ions so you have ultrapure water going into the electrolyzer,” said Ren. “Now, you can just acidify it a bit, then put ion-containing water into the electrolyzer, and it lasts for more than 300 hours without apparent issues.” The acid used is continuously recirculated, meaning it never leaves the system. This is important because it offers both environmental benefits and cost savings. Interestingly, the choice to use reclaimed wastewater over purified water could cut the cost of water treatment for hydrogen production by roughly 47 percent. On the other hand, the energy cost associated with that water treatment could be reduced by about 62 percent. The team is now working with industry partners to test the approach on a larger scale and with pretreated seawater. They are also engaged in big-picture planning, having previously published a study that identified the ideal locations across the United States to pair hydrogen facilities with wastewater plants. The research moves toward making hydrogen viable to reduce carbon emissions in tough-to-electrify sectors like steel and fertilizer manufacturing.