Copyright Interesting Engineering

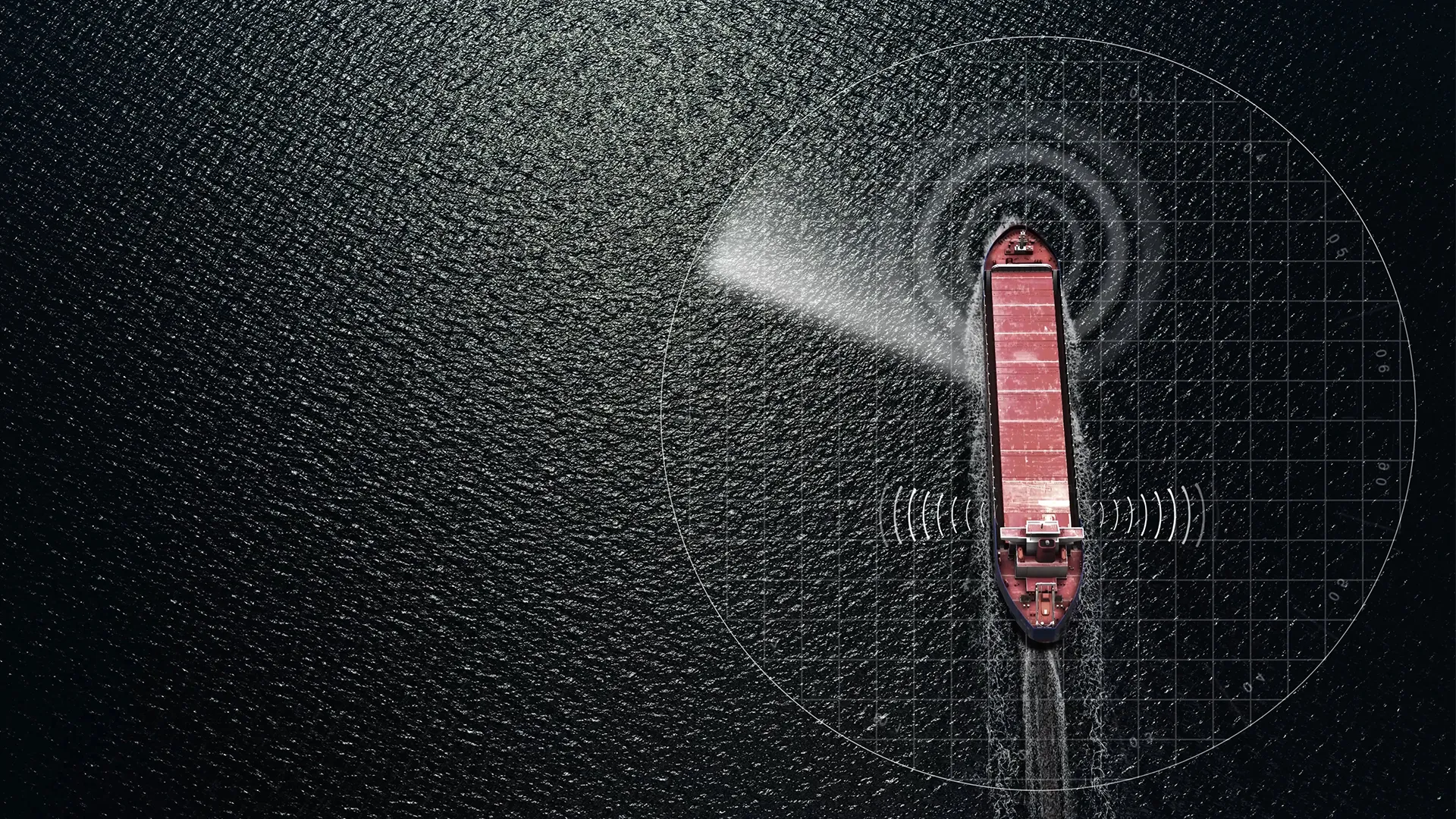

Long before modern navigation, sailors looked to the stars and followed constellations to cross open seas. Centuries later, diesel engines, radar, and GPS reshaped that journey—turning intuition into instrumentation. Yet even as the oceans became mapped, networked, and constantly monitored, ships still relied on human crews to interpret data, navigate uncertainty, and make critical decisions in real time. That’s starting to change. With the rise of autonomous shipping systems, control at sea is becoming increasingly software-defined. So what exactly is autonomous shipping, and what does it mean in engineering terms? At its core, autonomous shipping uses advanced control systems, machine learning, and sensor fusion to operate vessels with minimal or no onboard crew. Depending on the level of autonomy, ships may be remotely supervised from land or operate fully independently. Many can already handle route planning, navigation, and obstacle avoidance in real time. But autonomy is not absolute—understanding how these systems function, and when human oversight is still required, is key to grasping where maritime transport is heading next. Inside the AI and control systems powering autonomous ships Autonomous ships, particularly cargo vessels that transport goods, depend on a complex network of sensors, data-processing units, and communication systems to give the vessel real-time environmental awareness. This integration, which combines data from radar, LIDAR, GPS, sonar, cameras, and AI, is critical for enabling the ship to make navigational decisions without constant human oversight. This means that these systems monitor nearby vessels, weather patterns, as well as obstacles such as buoys or coastlines. The onboard AI then analyzes the coming data, compares it with preloaded maps and navigation models, and determines the safest and most efficient route. When conditions change, the cargo ships can automatically adjust course, speed, or engine output to maintain optimal operation. They are additionally equipped with machine learning algorithms that allow predictive decision-making, meaning they can anticipate potential hazards rather than react to them. At the same time, remote operation centers on land receive constant data streams through satellite. This makes it possible for human supervisors to closely monitor performance, intervene when necessary, or take direct control during emergencies. How IMO classifies next-gen vessels Nevertheless, even at the highest levels of automation, autonomous ships are not fully crewless, independent, or universally regulated. In fact, most existing autonomous vessels operate under supervised autonomy. Data suggests that semi-autonomous ships currently dominate the autonomous ships sector. They reportedly captured over 95 percent of the market share in 2023, primarily due to practical advantages over fully autonomous vessels. This means that human operators must still oversee their activity from shore-based control centers. So, rather than replacing humans, the technology is shifting maritime roles towards remote oversight and system management. Based on their level of autonomy, the International Maritime Organization (IMO) classifies autonomous ships into four different categories, with Degree 1 referring to vessels equipped with basic onboard automation. These are followed by remote-controlled ships with crew (Degree 2), in addition to remote-controlled ships without crew (Degree 3), as well as fully autonomous ships capable of independent navigation and decision-making (Degree 4). Early deployments That said, several major projects have recently started exploring the true potential of autonomous shipping technology. In Norway, the Yara Birkeland, made by the technology company Kongsberg Maritime, became the world’s first fully electric, zero-emission, and autonomous container ship. The 262-feet-long ship, which transports fertilizer between the ports of Porsgrunn and Brevik, has completed more than 250 voyages and transported over 35,000 containers over the past three years. Meanwhile, in collaboration with Finland’s state-owned ferry operator Finferries, Rolls-Royce Marine successfully tested the world’s first fully autonomous ferry, the Falco, near Turku in 2018. It carried 80 passengers without a single crew member on board. “Today marks a huge step forward in the journey towards autonomous shipping and reaffirms exactly what we have been saying for several years that autonomous shipping will happen,” Mikael Makinen, Rolls-Royce commercial marine president, said at the time. At the same time, in 2020, Japan launched The Nippon Foundation MEGURI2040 Fully Autonomous Ship Program, which aims to reach full-scale commercialization of fully autonomous ship technology by 2025. Engineering and economic benefits If implemented effectively, autonomous shipping has the potential to reshape global maritime transport. Improved safety is one of its most significant promises, as human errors are responsible for most maritime accidents. Automated navigation systems can help reduce this risk by maintaining constant vigilance and consistent decision-making under conditions that might overwhelm human crews. Automation can also boost operational efficiency and optimize routes, minimize fuel consumption, and reduce downtime due to port congestion or scheduling delays. This will ultimately lead to lower operational costs and improved fleet utilization for shipping companies. Reduction in crew requirements is yet another great advantage. With ships able to operate with smaller crews or none at all, the shift could simplify recruitment challenges and drive down labor costs. For countries such as Japan, which face labor shortages in the maritime sector, automation could help sustain coastal logistics and keep vital shipping routes active. Furthermore, smarter fuel use could help reduce emissions across the maritime sector. Also, by enabling remote management, these ships allow operators to oversee entire fleets from centralized control centers. Why full autonomy at sea is still out of reach But full autonomy remains out of reach, as it faces massive engineering, legal, and ethical hurdles. Technological readiness remains one of the greatest challenges because integrating sensors, AI, and remote control systems into a certified fail-safe solution is complex. Meanwhile, regulatory hurdles add an extra layer of difficulty, as international maritime law still lacks clear standards for fully autonomous vessels and their liability in case of accidents. There are also cybersecurity concerns. Increased digital connectivity exposes ships to hacking or data manipulation risks, where even a small breach in navigation or communication systems could have serious consequences. Moreover, high development costs and limited global infrastructure continue to slow adoption, especially for smaller operators and ports not yet equipped to support remote-controlled or crewless vessels. Finally, full automation could have a major impact on maritime employment. As the technology advances, the demand for traditional seafaring roles is expected to decline. While new jobs will likely emerge in remote operation, data analysis and system management, the transition could still be difficult for crews who have spent decades working at sea. This is why training programs and re-skilling initiatives will be essential to ensure that automation supports the maritime workforce.