Even in developed countries, clean water is under threat from pollutants that traditional treatment plants struggle to remove. Pesticides, pharmaceutical residues, industrial chemicals, microplastics, dyes, and PFAS continue to enter the water cycle.

According to the German Environment Agency (UBA), 40 active pharmaceutical ingredients were already detected in drinking water by 2023. Levels are even higher in groundwater, surface water, and wastewater run-off.

Conventional treatment systems often fail to remove these substances due to technical, environmental, or financial limitations.

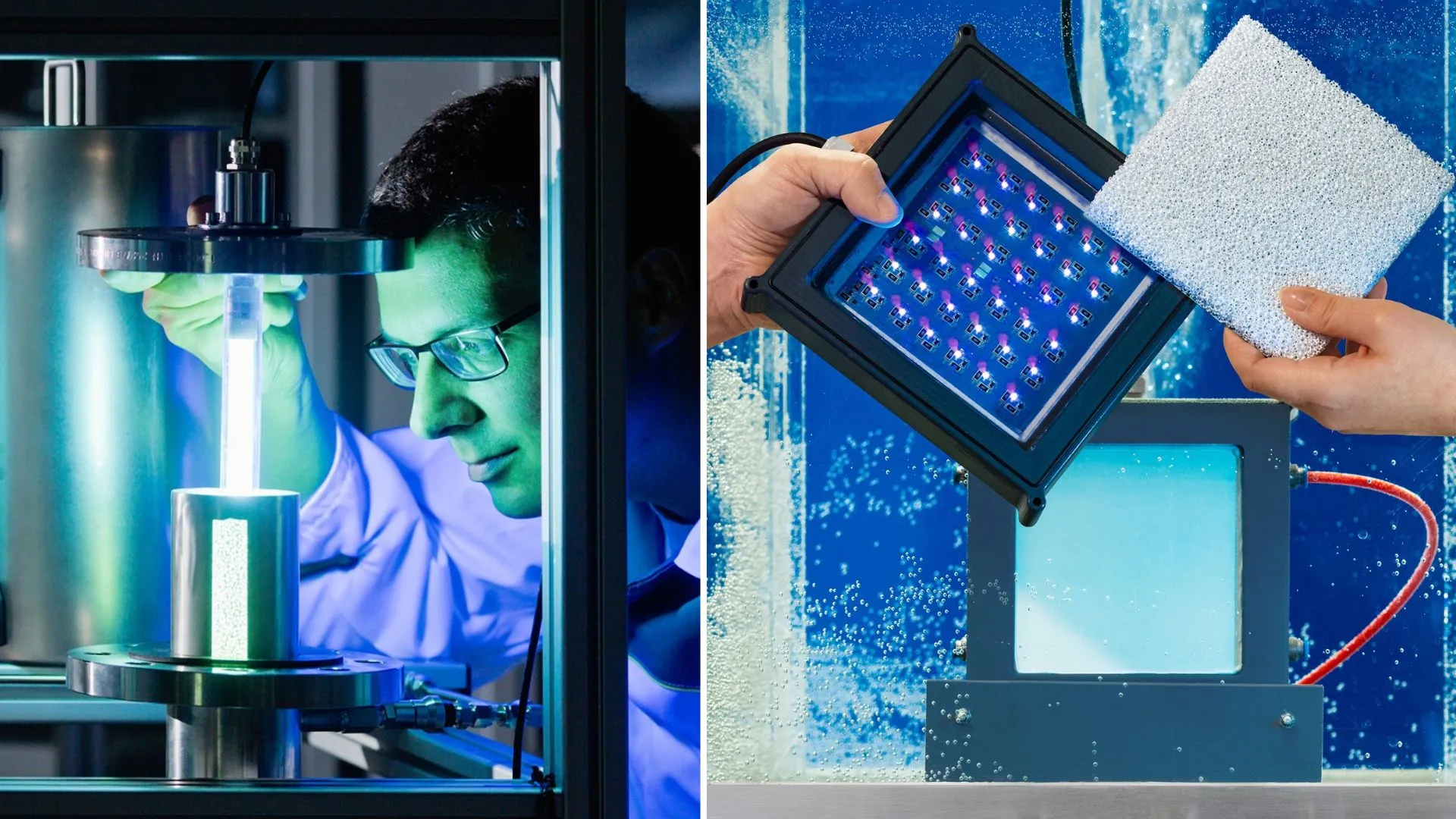

Researchers at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden are tackling this challenge with an innovative approach.

On October 1, a team of scientists revealed that they are developing compact foam ceramics with functional coatings that use photocatalytic oxidation to break down persistent pollutants effectively.

How photocatalytic foam works

“By exposing the functionalized surfaces to UV light, highly reactive radicals are created in the treated water, which decompose organic impurities. This process does not produce any undesirable by-products, nor does it require additional oxidizing agents such as ozone,” explained Franziska Saft, a research scientist at Fraunhofer IKTS.

She highlights that the solution focuses on industrial processes and wastewater treatment, where conventional systems fall short.

The efficiency of the process relies on close contact between the pollutant, the catalyst, and light. The foam ceramics’ porous, network-like structure provides extensive surface area for catalysts and adsorbents. With an open porosity of up to 90 percent, the foam also allows excellent light penetration.

“Our foam ceramics provide plenty of space for integrating various catalysts. This allows us to create a highly reactive surface area, enabling high catalytic conversions even when only thin layers are applied to the foam ceramic. The catalysts must be stabilized on the foam so they are not rinsed out with the wastewater flow,” added Daniela Haase, a project team member.

On-site piloting and customization

Fraunhofer IKTS is taking a hands-on approach by developing the wastewater treatment systems themselves. Their work includes designing multifunctional foam ceramics with optimized geometry, selecting appropriate catalyst coatings, and integrating energy-efficient UV LEDs.

Reactor designs are tailored to customer needs, allowing integration into existing systems and application-specific piloting at industrial sites.

Clients include pharmaceutical, semiconductor, paper, dairy, and textile companies that want to remove pollutants before wastewater reaches municipal treatment plants. By treating water on-site, they prevent harmful substances from entering the wider aquatic environment.

Promising results and future plans

Early pilot applications of the photocatalytic ceramic foam systems have shown significant success in breaking down pollutants. The research teams are further improving efficiency through advanced catalyst designs and combining them with adsorption materials.

Looking ahead, Fraunhofer IKTS aims to scale the technology for broader industrial adoption, positioning it as a key component of modern water management cycles.

By providing a compact, sustainable, and highly effective solution, the researchers are contributing to environmental protection and securing clean water resources for the future.