Copyright Interesting Engineering

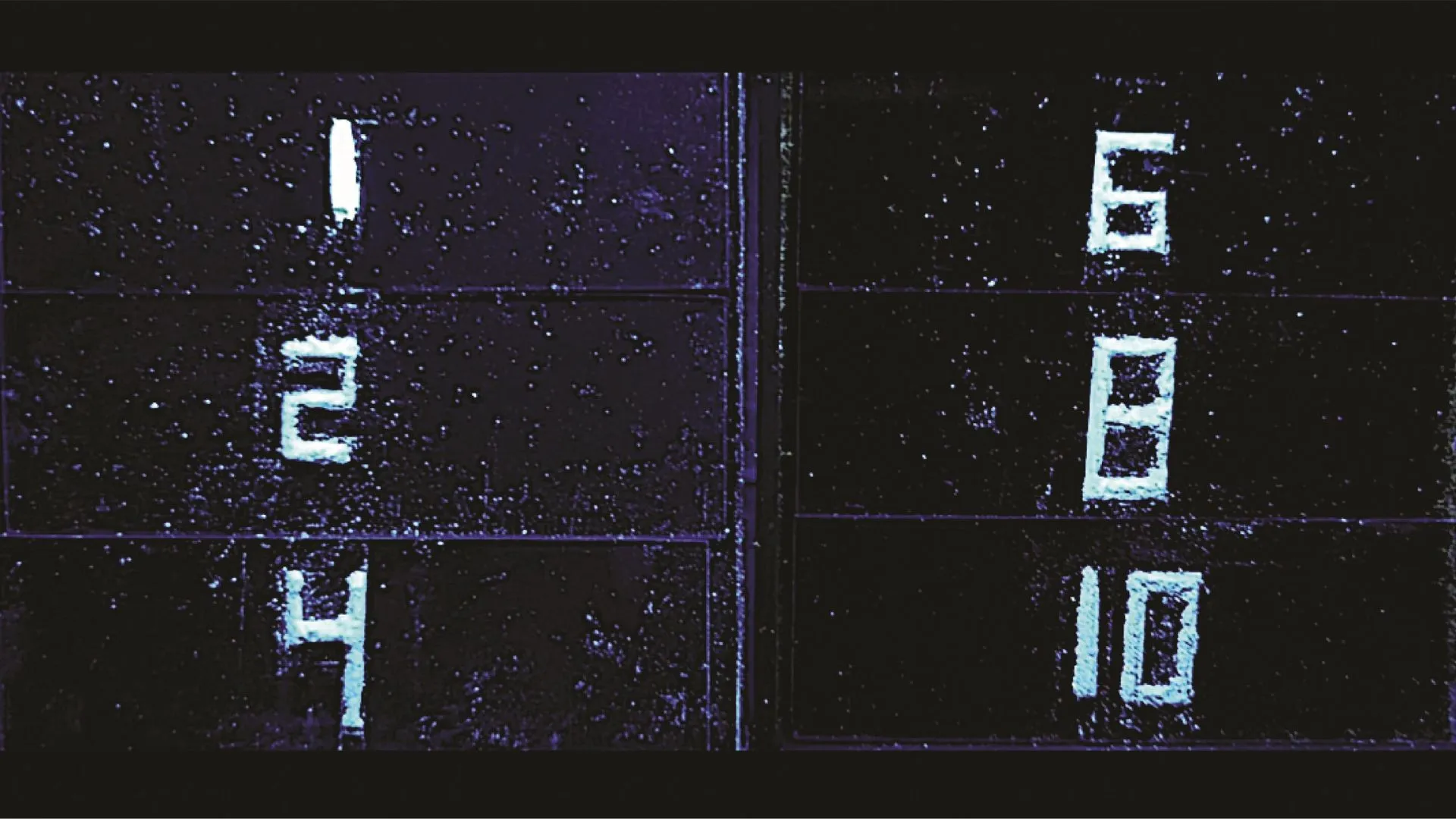

An eco-friendly substitute has been developed for the light-emitting materials used in modern display technologies, such as TVs and smartphones. The new material uses a common wood waste product to create a greener future for electronics, removing toxic metals and avoiding complex, polluting manufacturing methods. Researchers from Yale University and Nottingham Trent University have designed it. Specifically, the team utilized lignin, a substance naturally found in plant cell walls that is also a major by-product of the wood pulping and paper industry. The challenge of current technology Photoluminescent solid-state materials, often referred to as light-emitting materials, function by absorbing ultraviolet (UV) light and subsequently re-emitting that energy as visible light. This ability to “glow” makes them ideal for high-tech products, such as display technologies in sensors, security inks, and biomedical imaging. However, the current light-emitting materials are typically based on toxic metals and non-renewable resources. Moreover, making them typically requires complex, multi-step processes that generate hazardous chemical waste. The main goal for the researchers was to innovate, creating these vital materials from sustainable, green sources using processes that generate minimal waste and risk. “In this study, we not only simplified the synthesis of these materials but also utilized abundant waste streams to produce tunable materials in a safer way,” said Dr. Darren Lee, study co-author from Nottingham Trent University. The science behind the green glow Lignin was mixed with histidine, a simple amino acid, as part of this work. The result is a range of solid-state materials that fluoresce under UV light and boast easily tunable photoluminescent properties. Interestingly, the material’s preparation requires only green solvents — namely, water and acetone — which simplifies the synthesis and reduces the environmental impact. Computational modeling revealed how molecular interactions between lignin and histidine enable this unique light-driven proton transfer. The fluorescence effect relies on a known but rarely examined process called Excited State Proton Transfer (ESPT). Using computational modeling, the researchers uncovered how the molecular interactions between lignin and histidine enable this light-driven proton transfer. Specific structures in lignin, known as “phenolic groups,” absorb UV light and become energized. While in this energized state, the lignin functions as a photoacid, transferring protons to the histidine inside the solid material. When the lignin relaxes, it releases light at room temperature. Notably, some materials continued to glow briefly even after the UV source was removed. “The concept of ESPT isn’t new, it is well known in pure phenolic molecules,” said Dr. Ho-Yin Tse, first author and a researcher from the Center for Green Chemistry and Green Engineering at Yale University. “But what is interesting is that lignin’s natural phenolic structures—present throughout the macromolecule—can inherently support this kind of photoacid behavior, and this effect has rarely been examined in this context,” Tse added. The insights explain the mechanism by which biopolymers achieve efficient, metal-free light emission. The successful development of this metal-free, waste-derived material is a major step toward sustainable manufacturing in the electronics and lighting industries. The study was published in the journal Chem.