Copyright Interesting Engineering

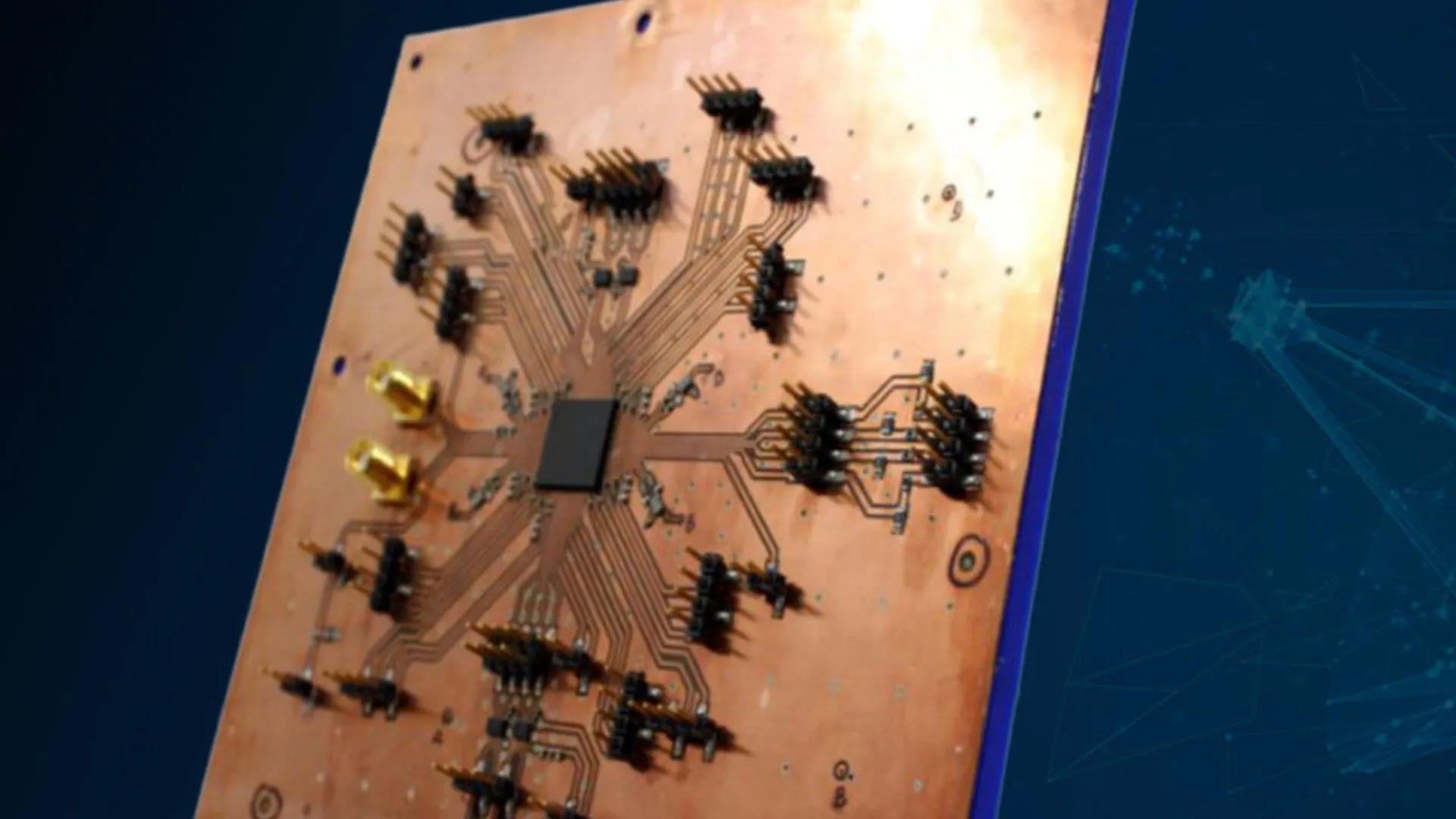

A cutting-edge 3D-printed antenna has been developed to enable stronger, flexible wireless electronics. It tackles the long-standing problem of signal failure in flexible electronics caused by bending, movement, and environmental changes. Interestingly, this antenna allows communication systems to be fully integrated into structures, turning surfaces like drone wings and fabric into high-speed electronic arrays. Announced on October 20, the development comes from researchers led by Washington State University (WSU) in the US. “This proof-of-concept prototype paves the way for future smart textiles, drone or aircraft communications, edge sensing, and other rapidly evolving fields that require robust, flexible, and high-performance wireless systems,” said Sreeni Poolakkal, co-first author and a PhD student in WSU’s School of Electrical Engineering and Computer Science. New design overcomes problems The growing reliance on wireless technology in modern devices demands continuous innovation in antenna design to achieve faster, more reliable connections. A major obstacle to the widespread adoption of flexible antennas is signal failure. These antennas are highly susceptible to errors when subjected to bending or movement, such as in wearable electronics or vibrating vehicle components like airplane wings The physical movements change the antenna’s shape, which destabilizes the wireless connection and causes signal errors. Developments have been happening gradually in this realm to overcome these limitations. For instance, a prior research made a flexible 3D antenna inspired by the ancient Japanese art of kirigami. In this new development, the WSU team turned to 3D printing to create a lightweight, flexible array of four antennas. For printing, the copper nanoparticle-based ink was designed by the team’s collaborators from the University of Maryland and Boeing. “Nanoparticle-based ink is actually very powerful in improving the performance for high-end communication circuits like what we’re doing,” said Subhanshu Gupta, associate professor and study’s co-author. Testing showed that the antennas maintain stable performance even when exposed to bending, high humidity, temperature changes, and salt. Processor corrects errors in real time The researchers also designed a special processor chip that works with the antennas to achieve precision in wireless communication. The chip corrects signal errors from the antenna in real time. It fixes issues caused by material deformities and vibrations. “We used this processor that we developed to correct for these material deformities in the 3D-printed antenna, and it also corrects for any vibrations that we see,” said Gupta. “The ability to do that in real time makes it very attractive. We were able to achieve robust, real-time beam stabilization for the arrays, something that was not possible before,” the author added. In testing, the lightweight prototype successfully sent and received signals while moving. The antennas use low power, making the tech efficient for various devices. The antennas are built as small, scalable tiles. This tile design allows for the easy building of much larger arrays. To demonstrate this scalability, the researchers successfully assembled four of the antenna arrays to create a total of 16 antennas. The lightweight and scalability make the system ideal for on-device implementation across many industries. If widely adopted, these new 3D-printed flexible, or conformal, antenna arrays could benefit aviation, automotive, and spacecraft design industries. The findings were reported in the journal Nature Communications.