Copyright Interesting Engineering

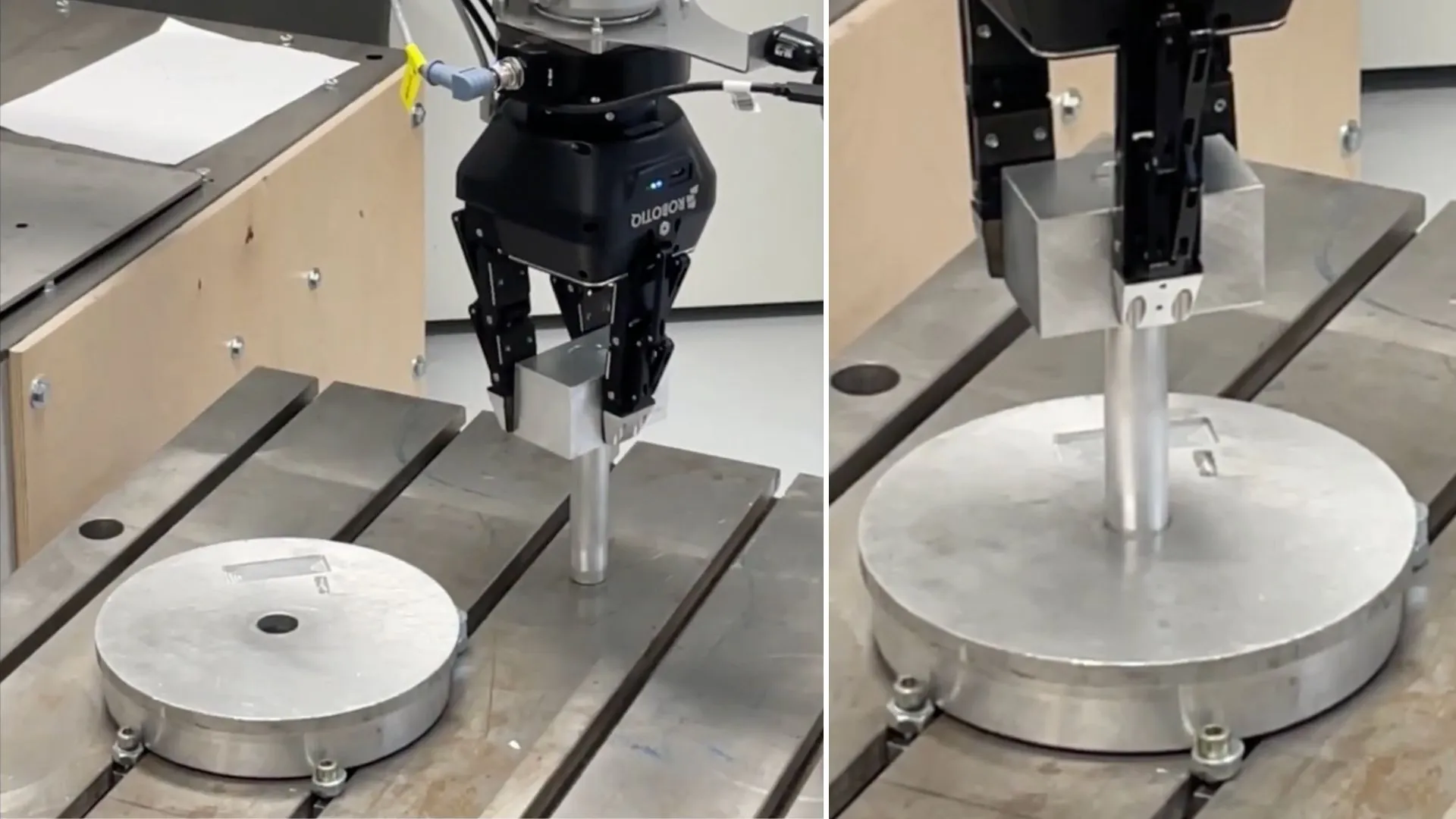

Researchers in China have developed a new AI-driven robotic system that successfully performs one of the most complex and critical maintenance tasks inside a fusion reactor, achieving an accuracy of less than 0.1 mm. This breakthrough, from the Hefei Institutes of Physical Science, directly tackles the massive challenge of “peg-in-hole” assembly, which is a common but time-consuming task for replacing components. “Periodic maintenance is essential to ensure the sustained functionality of fusion reactors. This process requires a wide range of remote operations, from handling large structural payloads to assembling small components such as bolts,” said the researchers in a new study. Using deep reinforcement learning The new system uses deep reinforcement learning (DRL) to guide a robot, much like human hand-eye coordination. “We propose a novel DRL-based approach that, unlike conventional methods, integrates data from a two-dimensional (2D) camera and an F/T sensor,” added the study. This approach bypasses the need for advanced 3D sensors, which struggle to operate reliably in the high-radiation and smooth, reflective metal environment of a reactor’s interior. This development is part of a larger push to automate fusion plant maintenance. Future fusion plants, such as the massive ITER project, will require regular, difficult maintenance. The current “human-in-the-loop” method used in existing reactors, like the Joint European Torus (JET), is a major roadblock to commercial viability. This manual process is incredibly slow; a past upgrade at JET, for instance, required engineers to handle 7,000 assemblies over 17 months. Such prolonged downtime is not feasible for a commercial power plant. Automating these tasks is essential. “By introducing a 2D camera, the method effectively resolves the peg-hole alignment stage, a challenge that many other assembly methods tend to avoid,” remarked the researchers. Supporting hardware and navigation To support this advanced AI, the researchers also engineered the necessary heavy-duty hardware. The team designed a novel robotic joint capable of moving massive reactor components. “By removing the sun gear from the traditional planetary gearbox, researchers created additional space for power and control cables without compromising compactness,” explained a press release. This new joint achieves an ultra-high reduction ratio of 13,806:1, allowing it to deliver an immense 139 kNm of torque with exceptional precision, making it ideal for the brute-force-yet-delicate task of maneuvering large components within the reactor vessel. Alongside the new hardware, the team also developed a sophisticated perception model to help the robot navigate. This system, named TCIPS, is a Transformer-based AI model that processes 3D point cloud data, the information a robot “sees.” It intelligently segments this complex data into basic geometric shapes like planes, spheres, and cylinders. By better understanding its environment, the robot can more effectively perceive and navigate the cluttered and complex interior of the reactor, avoiding obstacles and locating work areas. “Together, these innovations mark a significant step toward building intelligent, heavy-duty robotic systems capable of carrying out complex and high-risk maintenance tasks in future fusion power plants,” concluded the press release.