Copyright Interesting Engineering

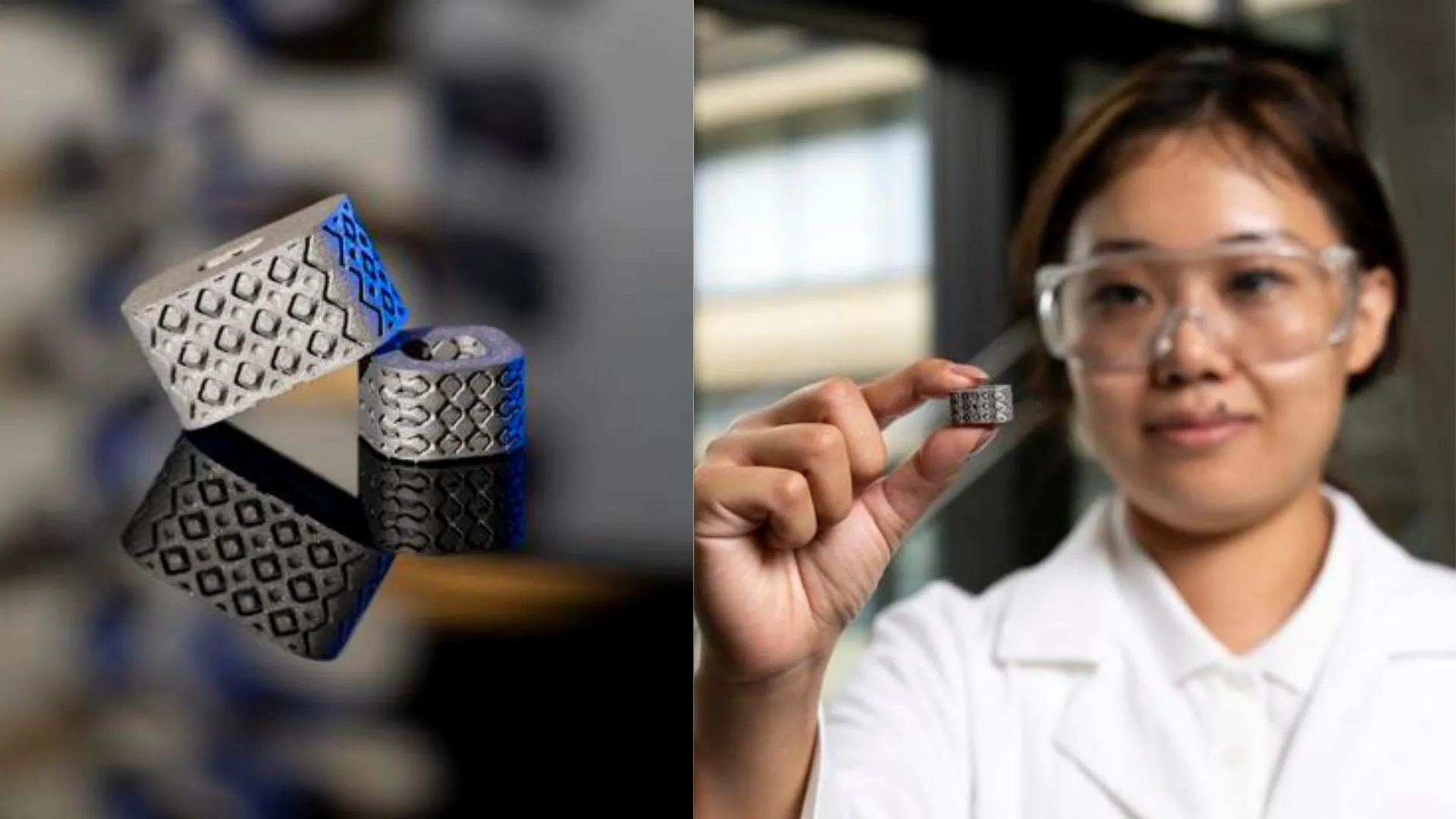

A collaboration between civil engineering and neurosurgery at the University of Pittsburgh could reshape spinal fusion surgery. Associate Professors Amir Alavi, Nitin Agarwal, and D. Kojo Hamilton have secured a $352,213 NIH R21 grant to create the first self-powered spinal implant capable of sending real-time data from inside the body. The project, titled “Wireless Metamaterial Interbody Cage for Real-Time Assessment of Lumbar Spinal Fusion In Vivo,” aims to make spinal fusion recovery safer by allowing doctors to track healing remotely and intervene before complications arise. Each year, nearly a million Americans undergo spinal fusion surgery. The procedure fuses two vertebrae using a metal cage and bone graft, held together by screws and brackets. Recovery monitoring still relies on X-rays and patient symptoms. “After implanting the hardware, we monitor it using X-rays and symptoms presented by the patient,” said Agarwal, co-principal investigator and associate professor in the Department of Neurological Surgery. “This means patients have to make in-person visits and subject themselves to radiation.” Since the healing process is hard to monitor continuously, Agarwal said it’s not a connected healthcare experience. Although implantable wireless devices exist, they depend on batteries and electronics, limiting their longevity. That’s where Alavi’s engineering background came in. As a PhD student, he developed sensors to monitor bridge infrastructure. These sensors produced their own power and sent alerts when bridges showed signs of stress or weakening. He realized the same idea could apply to spinal implants. “No batteries, no antennas, no electronics in vivo, no worries!” said Alavi, principal investigator and associate professor in civil and environmental engineering. “By blending metamaterial design with nano-energy harvesting, we create fully battery-free, electronics-free implants that power themselves through contact electrification.” From bridges to the human spine Alavi’s team uses metamaterials, human-made composites with interwoven conductive and non-conductive layers. These structures harvest energy and transmit signals when pressure is applied. In 2023, Alavi and Agarwal began integrating this technology into spinal fusion cages. Their research, detailed in Materials Today, describes implants that both stabilize and monitor the spine during recovery. “We’re creating cages for spinal fusion surgery that, like human cells, have a natural, built-in intelligence,” Alavi said. As the spine heals, the implant’s signal changes. “If the spine is healing, the bone starts carrying more of the load and the implant’s self-generated signal naturally drops,” Alavi explained. “Right after surgery, the signal is stronger because the vertebral endplates press harder on the cage.” AI-designed and cloud-connected implants Signals from the implant are received by an electrode on the patient’s back and transmitted to the cloud, where doctors can analyze them in real time. This could allow early intervention before major complications develop. Alavi’s team also uses generative AI to personalize the cage design. “We can scan the patient’s spine and then design and print the cage to fit perfectly,” he said. These metamaterial cages not only adapt to each patient but also generate their own power. The team has tested the devices in vitro and confirmed the concept works. With NIH funding, the next phase will involve in vivo animal trials. “If it works,” Agarwal said, “then the next step is human testing.” “By blending the clinical and the bench expertise, we have a better chance of translating the science into patient use,” he added. “Improving safety and outcomes while creating more connected health care.”