Copyright Interesting Engineering

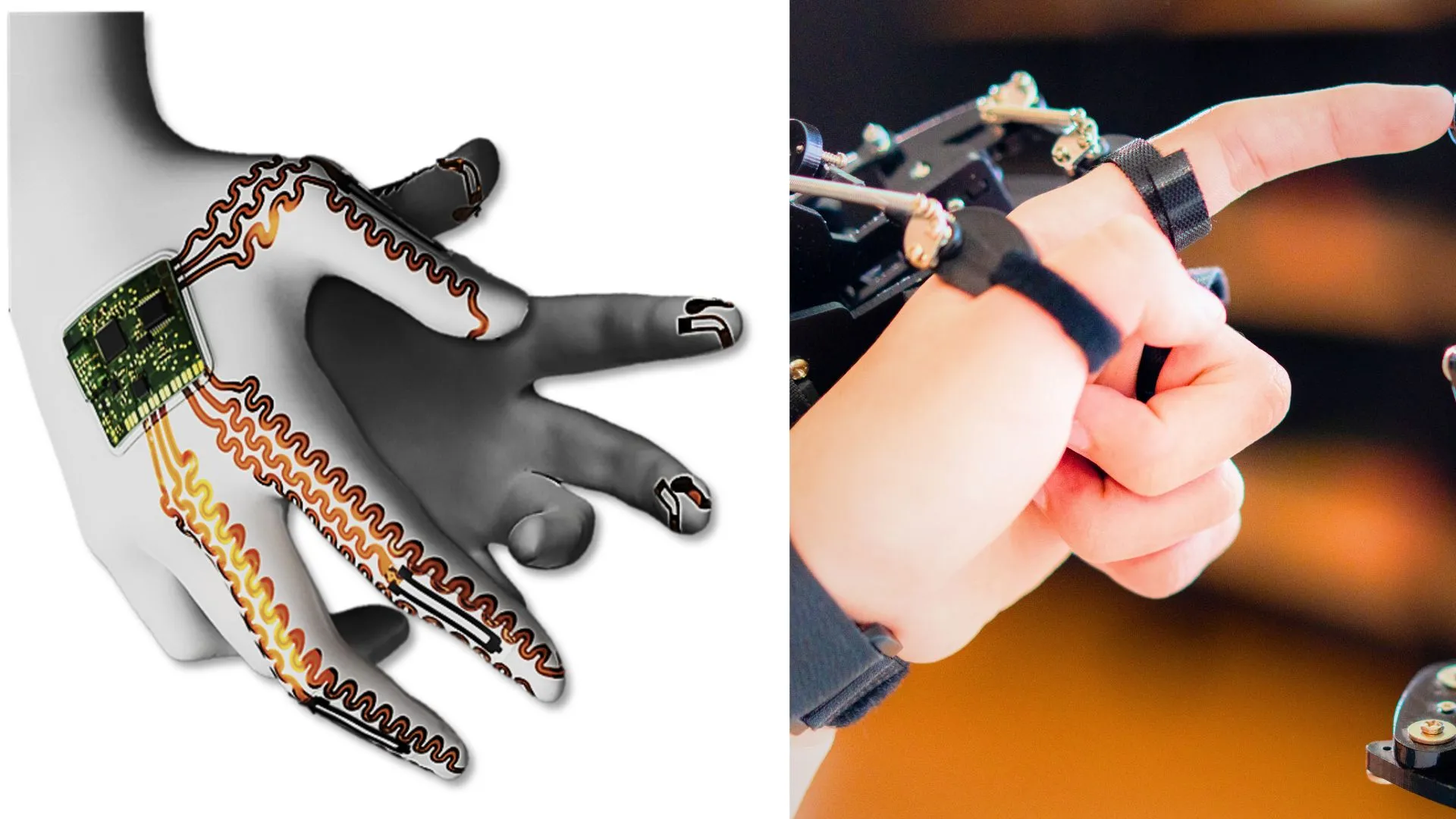

Researchers in the United States recently worked on AI-powered muscles made from lifelike materials paired with intelligent control systems. Their technology is claimed to be capable of learning from the body and can adapt in the real time. This helps create motion that feels natural, responsive, and safe enough to support recovery. Researchers from the Georgia Institute of Technology used hierarchically structured fibers, which are flexible materials built in layers, much like muscle and tendon. They can sense, adapt, and even “remember” how they’ve moved before. Flexible and responsive artificial muscles “When people think of robots, they usually imagine something like The Terminator or RoboCop: big, rigid, and made of metal,” said Hong Yeo, the G.P. “Bud” Peterson and Valerie H. Peterson Professor in the George W. Woodruff School of Mechanical Engineering. “But what we’re developing is the opposite. These artificial muscles are soft, flexible, and responsive — more like human tissue than machine.” Yeo trains machine learning algorithms to adjust those pliable materials in real time with the right amount of force or flexibility for each task. The researcher revealed that these muscles don’t only respond to commands. “They ‘nlearn from experience. They can adapt and self-correct, which makes motion smoother and more natural.” The result of that research is deeply human. For someone recovering from a stroke or limb loss, each deliberate movement rebuilds not just strength — it rebuilds confidence, independence, and a sense of self. Creating lifelike muscles isn’t easy. They need to be soft but strong, responsive but safe. And they must avoid triggering the body’s immune system. That means building materials that can survive inside the body — and learn to belong there, according to a press release. Enabling artificial muscles to execute a range of pre-programmed movements Published in Materials Horizon, the work aimed at augmenting intelligence in artificial muscles are summarized, focusing on advancements in functional materials, structural designs, and manufacturing techniques. This review emphasizes memory-based intelligence, enabling artificial muscles to execute a range of pre-programmed movements and refresh stored actuation states in response to changing conditions, as well as sensory-based intelligence, which allows them to perceive and respond to environmental changes through sensory feedback, according to the study. Researchers also addressed the remaining challenges in scalability, dynamic reprogramming, and the integration of multi-functional capabilities and discuss future perspectives of augmented intelligent artificial muscles to support further advancements in the field. “We always think about not only function, but adaptability,” Yeo said. “If it’s going to be part of someone’s body, it has to work with them, not against them.” His team calibrates these synthetic fibers like precision instruments — tested, adjusted, and re-tuned until they operate in sync with the body’s natural movements. Over time, they develop a kind of “muscle memory,” adapting fluidly to changing conditions. That dynamic adaptability, Yeo explained, is what separates a machine from a prosthetic that truly feels alive, as per the release.