Copyright Interesting Engineering

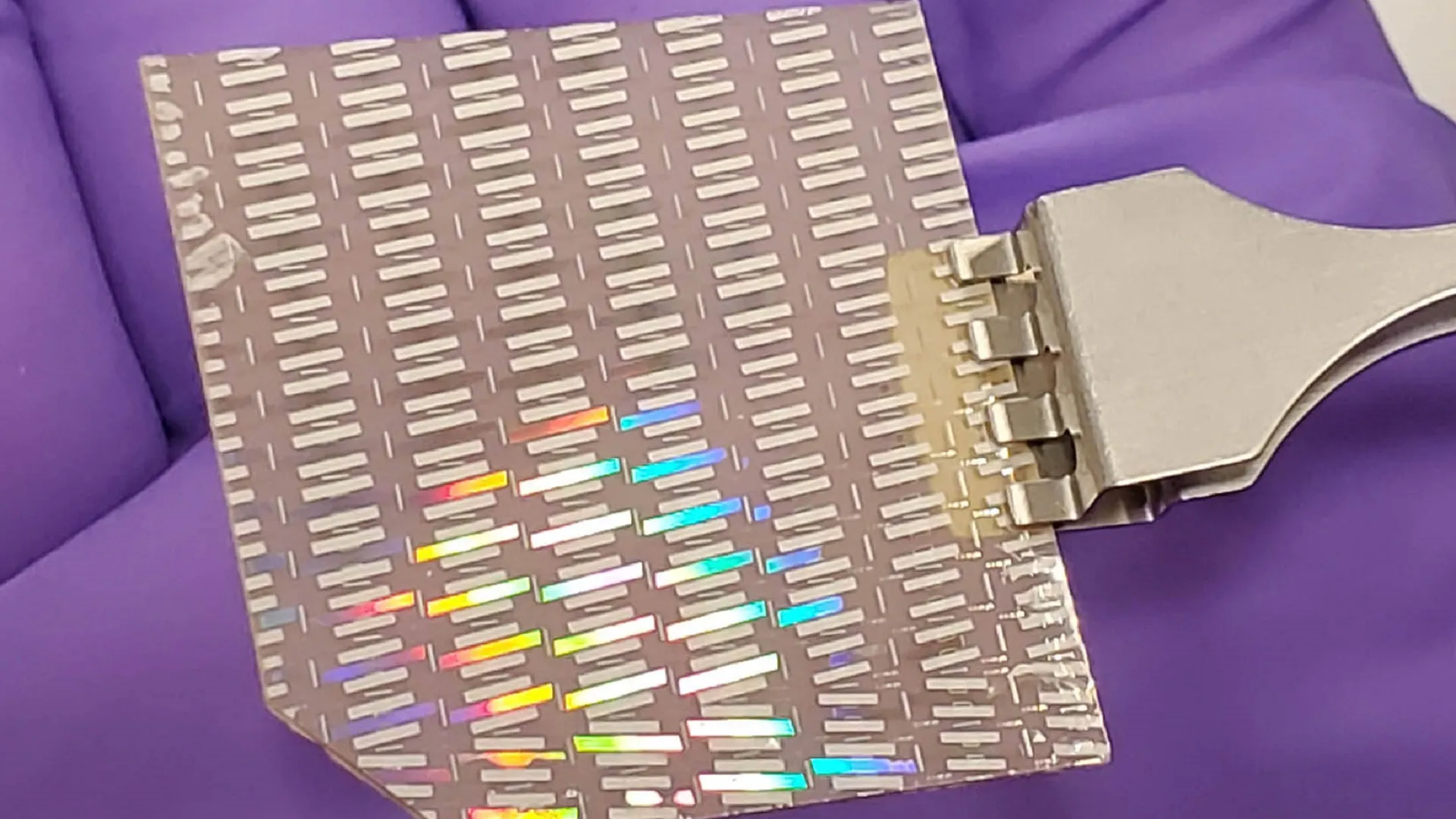

Researchers in the US have developed microelectronic sensors that are capable of surviving temperatures as high as 1,832 degrees Fahrenheit and intense radiation levels inside advanced nuclear reactors. The new microchip, which was designed by engineers at the University of Maine (UMaine), can withstand both the in-core radiation levels, and the extreme temperatures that exist within these advanced nuclear reactors According to the scientists, these sensors could potentially redefine how power plants in the US, which provide approximately 20 percent of the nation’s energy, are monitored and maintained. “This is the first demonstration of a microchip technology capable of measuring reactor power up to 800 degrees Celsius, or about 1,500 degrees Fahrenheit,” Mauricio Pereira de Cunha, the Roger Clapp Castle and Virginia Averill Castle professor of electrical and computer engineering and principal investigator on this project, revealed. New reactor-safe chips Nuclear engineers rely on sensors for feedback on whether the reactors are safe to operate and functional. These provide a wide range of parameters, including temperature, reactor power, neutron flux and strain on reactor walls. However, as the US moves toward deploying a new wave of high-temperature, high-efficiency reactors, existing commercial sensors can’t handle the extreme conditions they will face. To address the challenge, UMaine scientists unveiled a new type of sensor after two years of extensive testing and development. The nanotech-based microchip at the core of this system can survive extreme reactor conditions while delivering real-time data. This allows engineers to detect issues faster and lower maintenance costs. The chip can also measure reactor power at temperatures reaching 1,500 degrees Fahrenheit (about 800 degrees Celsius). As per Pereira da Cunha, the new sensors close a major gap in instrumentation for advanced nuclear systems such as microreactors, that operate at much higher temperatures than traditional reactors. “The commercially available sensors that measure power in nuclear reactors do not operate up to 800 degrees Celsius,” Pereira da Cunha, pointed out. “We have now proven that it can be done.” Reactor-ready microchips Recent tests at the Ohio State University Nuclear Research Laboratory, which is part of the US Department of Energy’s Nuclear Science User Facilities network, showed that the prototype was able to operate for an entire week without degradation in performance. “In addition to extreme temperatures, we’re now also exposing these sensors to intense, in-core levels of nuclear radiation at the same time,” Luke Doucette, the project’s senior research scientist and R&D program coordinator, said. “This adds an entirely new dimension of difficulty in terms of what types of sensor materials can survive in these conditions and remain functional,” Doucette stated in a press release. The researchers now plan to extend their nuclear sensor technology for wireless connectivity, which requires no batteries. In addition, it is powered and operated entirely by the wireless interrogation signal. They also aim to establish a lab focused on materials and sensors for advanced reactors. “The successful development of these sensors will address and alleviate technology barriers that currently hinder the rollout of advanced nuclear reactors,” Pereira da Cunha concluded. The team hopes continued support will position the university as a key player in this emerging field and help meet the nation’s growing energy needs.