A team at Rice University has unveiled a fast and cleaner method to extract aluminum and strip toxic metals from bauxite residue, also called red mud.

The hazardous by-product of aluminum production has long plagued the industry, but this new technique could mark a breakthrough in waste management.

Flash heating clears toxic metals

The process relies on flash Joule heating (FJH), which sends a high-power electrical pulse through the material for less than one minute.

A small dose of chlorine gas works in tandem with the pulse to vaporize harmful metals. What remains is an aluminum-rich residue that can be reused.

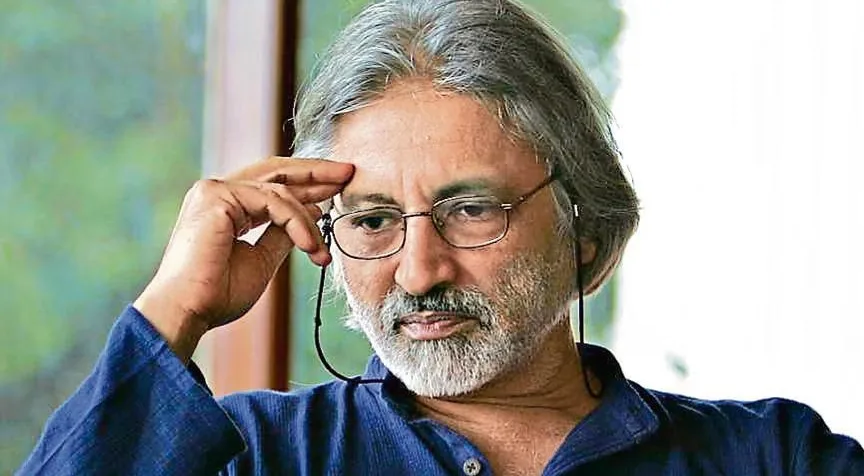

James Tour, professor of chemistry and materials science at Rice, called the achievement an industrial milestone.

“Our research presents a potential game-changing solution for the red mud crisis,” he said. “This advance is massive from an industrial perspective, turning what was once a toxic liability into a valuable asset in under one minute.”

Researchers demonstrated that the purified aluminum can return to the production cycle or be converted into durable ceramic tiles and bricks.

Each year, millions of tons of red mud accumulate worldwide, threatening communities with river contamination and storage disasters.

Traditional cleanup approaches often involve prolonged heating or corrosive chemicals, both costly and environmentally harmful.

Postdoctoral researcher Qiming Liu, a co-first author, stressed the efficiency of the new approach.

“The speed and simplicity of this method set it apart,” Liu said. “In just 60 seconds, we extracted 96% of the iron and nearly all the toxic species, while retaining almost all the aluminum.”

The process avoids water and solvents while also removing sodium salts, a key improvement. The result is a safer material that no longer carries the caustic nature of untreated red mud.

Toward sustainable industry solutions

The team believes the method has applications beyond aluminum production. Industries such as steelmaking, mining, and rare earth processing also generate high-volume waste streams that could benefit from FJH.

“What was once an environmental threat can now be transformed into building materials,” said co-first author Shichen Xu. “We have turned cleaned red mud into ceramics that are super hard, making them suitable for construction and aluminum recovery.”

The technique offers three major benefits – shrinking waste piles, cutting emissions, and reducing demand for new bauxite mining. For communities hit by red mud disasters, the advance represents a practical path forward.

Tour said the project is moving toward industrial deployment through Flash Metals USA, a Rice spinoff under Metallium Ltd. The company is working with aluminum producers to scale the process globally.

The study, published September 15 in ACS Applied Materials and Interfaces, included contributions from multiple Rice researchers and collaborators at the U.S. Army Engineer Research and Development Center.

Funding came from the Air Force Office of Scientific Research and the U.S. Army Corps of Engineers.