A cleaner way to extract lithium may be on the horizon.

A team of researchers at Rice University has developed a new membrane that selectively filters lithium from brines, offering a faster and more sustainable method to produce the element that powers nearly every rechargeable battery.

According to the study, the membrane achieved one of the highest selectivities for lithium among similar technologies while consuming considerably less energy.

The design can also be adapted to recover other minerals like cobalt and nickel and is compatible with existing industrial systems.

Most of the world’s lithium currently comes from saltwater brines through a process that relies on vast evaporation ponds and heavy chemical use. That method is both slow and environmentally damaging.

Rethinking lithium extraction

“The most widely used large-scale lithium extraction method today requires massive evaporation ponds and chemical precipitation,” said Qilin Li, the Karl F. Hasselman Professor of Civil and Environmental Engineering and co-director of Rice’s Nanotechnology Enabled Water Treatment (NEWT) Center.

“The process can take over a year to reach the target concentration and has fairly low lithium recovery rates. It also uses a lot of water, often in places that already experience water scarcity, and produces considerable amounts of chemical waste.”

The new membrane relies on electrodialysis. When an electrical current is applied, lithium ions pass through the barrier while other abundant elements—such as sodium, calcium and magnesium—are left behind.

“Typically when you apply an electrical field, all the positively charged ions will transport across the cation exchange membrane,” Li explained. “Lithium is actually a minor component in brine, but our membrane allows primarily lithium to transport across. Other ions stay behind.”

That high degree of selectivity makes the process far more energy-efficient than traditional electrodialysis, which is often used for desalination or wastewater treatment.

Smart design principles

The key innovation lies in embedding nanoparticles of lithium titanium oxide (LTO) into the membrane. The crystal structure of LTO is just the right size for lithium ions to move through, while blocking others.

To avoid defects, the Rice team grafted the LTO with amine groups, allowing it to blend evenly into a polyamide layer and form a strong, defect-free “skin.”

“This project builds on our work through the NEWT Center, so it draws on 10 years of research on nanomaterials and nanotechnology,” Li said. “We have learned how to incorporate nanomaterials into membranes and how to make nanocomposite membranes that fulfill a desired set of functions.”

Each of the three layers in the membrane can be independently optimized. That makes the platform versatile enough for selective extraction of other resources, including cobalt and nickel.

“Our goal was to develop a material that can extract lithium with minimum environmental impact,” Li said. “The smart design principles we used to develop the membrane architecture have ensured it can be adapted to help recover many other valuable resources from various waste streams.”

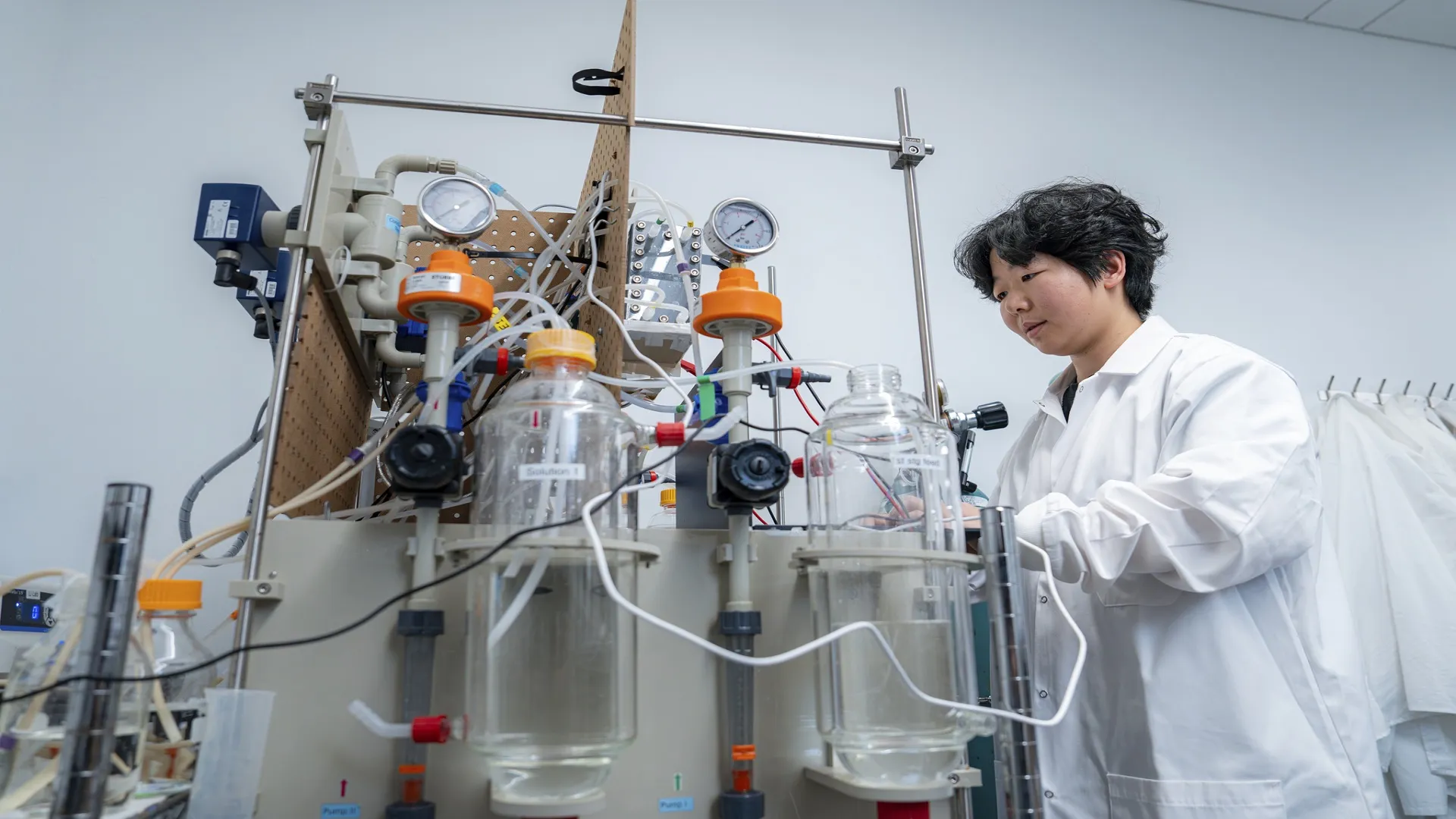

The researchers confirmed durability by running the membrane in an electrodialysis system for two weeks. It maintained its strength and performance without significant degradation.

“One of the important features of our membranes is their potential to be produced at scale, which could pave the way for their use in industrial settings,” said Jun Lou, the Karl F. Hasselmann Professor of Materials Science and Nanoengineering.

The findings of the study have been published in Nature Communications.