Japan-based Mitsubishi has announced the accomplishments of its autonomous robot, which is used to carry out underwater inspections in a nuclear reactor vessel.

The A-UT – autonomous underwater inspection device – from the house of Mitsubishi Heavy Industries (MHI) Group is tasked with checking for faults in the weld lines inside a reactor vessel at the core of a nuclear power plant.

A nuclear reactor vessel, which is operational, is highly radioactive and also works under high temperatures and high pressure. Therefore, it is not feasible for a human to carry out regular inspections inside the reactor vessel.

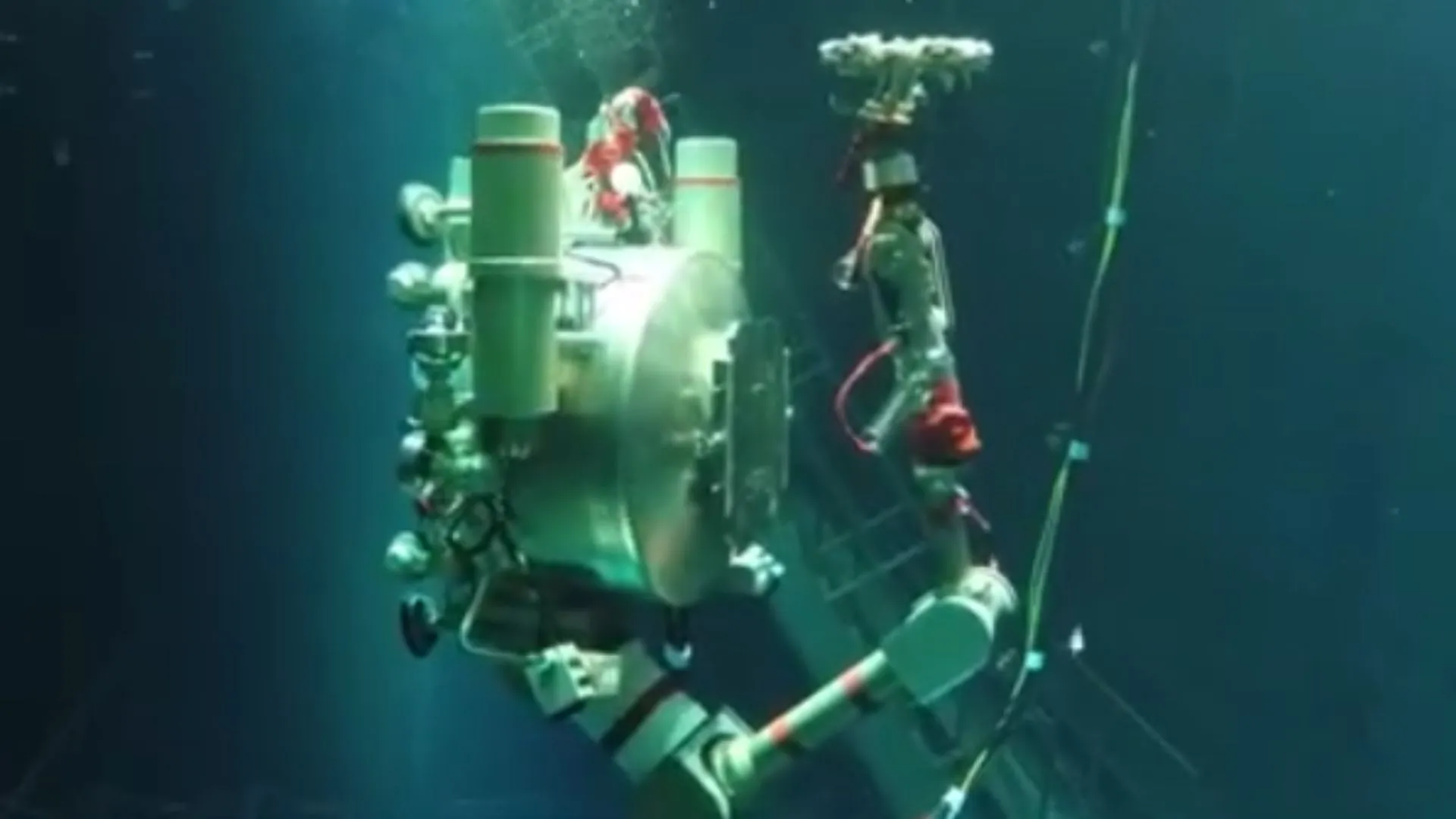

The A-UT is fitted with a seven-axis robotic arm with sensor pads at the end, and is designed specifically to do this.

A-UT robot for nuclear reactor vessel inspections

Mitsubishi says that the robot has been developed to carry out non-destructive inspections of nuclear reactor vessels in underwater environments.

It states that the robot has been working at pressurized water reactor power plants across Japan since 1995, and has been used at least 50 times.

The robot can be controlled remotely using a computer and joystick by operators. The robot navigates around the hazardous environment, swimming in the water inside the nuclear reactor vessel, sticking to the walls with vacuum-pad feet, and using a probe to carry out ultrasonic testing.

The company says that it can scan the walls of the reactor vessel at a speed of 200 millimeters per second, which leads to faster inspection. Moreover, deploying two units together inside a reactor vessel can greatly cut the time required for inspections.

The robot has a length of 5.9 feet (1.8 meters), 3.2 feet (1 meter) width, and a height of 2.9 feet (0.9 meters). It weighs 881 pounds (400 kilograms) and navigates using a thruster and travels on wall surfaces using wheels.

The robot’s operational scope ranges to a maximum water depth of 65 feet (20 meters).

Important role in clean energy generation

The A-UT developed by Mitsubishi is certified as the number one Maintenance Heritage by the Japan Society of Maintenology. Maintenance Heritage is defined as a “historic heritage related to maintenance technology, also constituting a cultural heritage of humankind.”

The robot has been operating for nearly three decades now, proving its relevance in ensuring the uninterrupted operations of the nuclear power plant.

Nuclear power plants employ advanced technology to generate power under extreme conditions. Therefore, timely monitoring of the reactor vessels and other components is a must to ensure safe and uninterrupted operations.

Doing a job that no other human can do reduces risks and provides a more detailed analysis through ultrasonic inspections than any human eye can provide.

There is likely going to be a resurgence of nuclear power in Japan under the leadership of Sanae Takaichi, the newly elected leader of the country’s ruling party. It is expected that she will push for the advancement of nuclear technologies like fusion to shift the country’s focus away from renewables like solar to nuclear energy.

The earlier governments in the country have also been pushing for building new nuclear power plants to meet the energy needs of the future. The Fukushima disaster was a major setback in the country’s nuclear program, but the government seems to be willing to look towards the future with renewed hope.

At such a critical time, the A-UT robot deserves to be praised for its efficiency in ensuring continued operations at nuclear power plants in the country.