Copyright researchsnipers

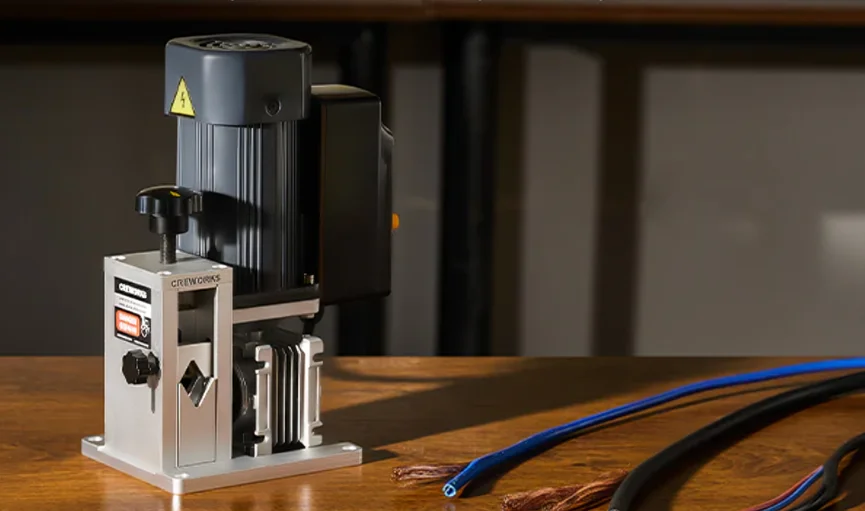

In today’s fast-paced business environment, efficiency isn’t just a buzzword—it’s a necessity. Companies dealing with electronics, manufacturing, or recycling often face time-consuming and labor-intensive tasks, with wire processing being a prime example. Manually stripping wires can be slow, inconsistent, and even risky. This is where the wire stripping machine comes in, offering a smarter, faster, and safer solution that boosts operational efficiency. Understanding Wire Stripping Machines Wire stripping machines are specialized devices designed to remove insulation from wires quickly and accurately. They come in various types, including manual, semi-automatic, and fully automatic models, each suited for different scales of operation. Businesses across electronics, recycling, and manufacturing industries rely on these machines to handle wires with precision and speed, making everyday tasks simpler and more reliable. Time-Saving Benefits One of the biggest advantages of wire stripping machines is the time saved. A task that could take hours manually—stripping hundreds of wires—can now be completed in minutes. This allows businesses to scale their operations without proportionally increasing labor costs. For companies working on tight deadlines, the ability to process wires quickly translates directly into faster project completion and improved overall productivity. Improving Accuracy and Consistency Manual wire stripping often leads to uneven results or even damaged wires. Wire stripping machines eliminate these inconsistencies, providing uniform stripping that preserves the integrity of the wire. This precision is especially critical in electronics manufacturing or projects involving delicate components, where even minor errors can result in costly rework. Consistent results enhance product quality and reduce waste, contributing to smoother operations. Reducing Labor Costs and Increasing Productivity Automation is a major factor in cost savings. By reducing reliance on manual labor, businesses can reallocate employees to higher-value tasks. The result is not just lower labor costs, but also a more productive workforce. Over time, the investment in a reliable wire stripping machine can pay for itself through improved efficiency and decreased operational bottlenecks. Enhancing Safety Manual wire stripping carries risks such as cuts, repetitive strain injuries, and exposure to insulation chemicals. Wire stripping machines minimize these hazards, creating a safer workplace. Companies can also ensure compliance with occupational safety standards, which protects both employees and the business from potential liabilities. Supporting Sustainability and Recycling Many wire stripping machines enable businesses to recover valuable metals like copper and aluminum from waste wires. This supports sustainable practices, reduces waste, and can even generate additional revenue through recycling. By combining efficiency with eco-friendly processes, companies can achieve operational goals while being responsible corporate citizens. Selecting the Right Machine for Your Business Choosing the right wire stripping machine depends on several factors: the types of wires you handle, your processing volume, the level of automation needed, and budget considerations. Features like speed, versatility, and ease of maintenance are also important. For businesses looking for a reliable solution, brands like Creworks offer models that balance efficiency, precision, and durability. Wire stripping machines transform a tedious, time-consuming task into a streamlined, efficient process. They save time, reduce labor costs, improve product quality, enhance safety, and support sustainability efforts. For businesses looking to boost operational efficiency, investing in a quality wire stripping machine is a strategic move that pays off in both the short and long term.