EV Batteries Plant Construction Industry Business Report 2025: Market To Reach $24 Billion By 2030 – Government Incentives And Emission Regulations Accelerate Expansion

By Date,MENAFN

Copyright menafn

Dublin, Sept. 17, 2025 (GLOBE NEWSWIRE) — The “EV Batteries Plant Construction – Global Strategic Business Report” report has been added to ResearchAndMarkets’s offering.The global market for EV Batteries Plant Construction was estimated at US$12.4 Billion in 2024 and is projected to reach US$24.0 Billion by 2030, growing at a CAGR of 11.7% from 2024 to 2030. This comprehensive report provides an in-depth analysis of market trends, drivers, and forecasts, helping you make informed business decisions.

The growing demand for electric vehicles (EVs) is the primary driver behind the rapid expansion of the EV batteries plant construction market. As governments and consumers increasingly focus on reducing carbon emissions and adopting cleaner transportation alternatives, the demand for EVs has skyrocketed. This, in turn, has led to an urgent need for a robust supply of high-performance, long-lasting batteries to power these vehicles. Manufacturers are investing heavily in building state-of-the-art battery production facilities to meet the escalating demand for EV batteries and support the growing global EV market.Government incentives and regulations are also playing a significant role in the expansion of EV battery plant construction. Countries around the world are implementing stricter emissions standards, providing subsidies, tax rebates, and grants to encourage the adoption of electric vehicles and the development of supporting infrastructure. For instance, the European Union, the U.S., and China have all committed to aggressive electric vehicle adoption goals and, in parallel, to the creation of more local EV battery manufacturing plants. These initiatives are catalyzing investments in battery plants and helping to ensure a reliable, geographically diverse supply of batteries that can meet regional demand.Moreover, the ongoing advancements in battery technology, such as solid-state batteries and fast-charging solutions, are prompting plant construction efforts to accommodate the latest innovations. Battery manufacturers are increasingly prioritizing the integration of cutting-edge technology into new plants, ensuring that production processes align with the latest advancements in battery chemistry and performance. These developments not only improve the quality and cost-efficiency of the batteries but also ensure that plants remain competitive in an ever-evolving market. How Are Technological Innovations Impacting EV Batteries Plant Construction? Technological innovations in battery chemistry and manufacturing processes are central to the growth of the EV batteries plant construction market. Advances in battery energy density, charging times, and lifespan are motivating manufacturers to build new plants or upgrade existing ones to accommodate these developments. For instance, the shift from lithium-ion batteries to solid-state batteries could transform the production process and, consequently, the infrastructure needed to manufacture these next-generation batteries. Solid-state batteries promise higher energy density, faster charging times, and improved safety, and plant facilities are being designed to meet the specific requirements for these advanced technologies.Automation and robotics are playing a crucial role in enhancing the efficiency and scalability of battery production. New plants are increasingly adopting automated systems to handle tasks such as assembly, testing, and quality control, allowing manufacturers to scale operations quickly and ensure consistent quality. These advancements are not only improving production speed and capacity but also reducing labor costs and minimizing human error, making the production process more reliable and cost-effective.Moreover, innovations in supply chain management and battery recycling are affecting the construction of EV battery plants. As concerns about resource scarcity and environmental sustainability grow, battery manufacturers are focusing on creating plants that integrate closed-loop recycling systems, which will allow them to reuse materials like lithium, cobalt, and nickel. This reduces reliance on raw materials and supports sustainable practices in the battery manufacturing industry. Advanced tracking and inventory management technologies are helping optimize the entire supply chain, ensuring that plants can operate at full capacity while minimizing waste and costs.

Report Features:

Comprehensive Market Data: Independent analysis of annual sales and market forecasts in US$ Million from 2024 to 2030. In-Depth Regional Analysis: Detailed insights into key markets, including the U.S., China, Japan, Canada, Europe, Asia-Pacific, Latin America, Middle East, and Africa. Company Profiles: Coverage of players such as ABEL Construction, AECOM, Barton Malow, Bechtel Corporation, Clayco and more. Complimentary Updates: Receive free report updates for one year to keep you informed of the latest market developments.

Key Insights:

Market Growth: Understand the significant growth trajectory of the Building & Infrastructure Component segment, which is expected to reach US$7.7 Billion by 2030 with a CAGR of a 10.7%. The Machinery & Equipment Component segment is also set to grow at 11.7% CAGR over the analysis period. Regional Analysis: Gain insights into the U.S. market, estimated at $1.5 Billion in 2024, and China, forecasted to grow at an impressive 11.0% CAGR to reach $14.5 Billion by 2030. Discover growth trends in other key regions, including Japan, Canada, Germany, and the Asia-Pacific.

Scope of Study:

Segments: Construction Type (New Plant Construction, Plant Expansion, Plant Renovation); Component (Building & Infrastructure, Machinery & Equipment, Energy Storage Systems, Control Systems & Automation) Geographic Regions/Countries: World; United States; Canada; Japan; China; Europe (France; Germany; Italy; United Kingdom; and Rest of Europe); Asia-Pacific; Rest of World.

Key Attributes:

Key Topics Covered: MARKET OVERVIEW

Tariff Impact on Global Supply Chain Patterns Electric Mobility Undergoes Tectonic Shift & Hurtles Toward a Different Future The Evolution of Battery Manufacturing in the Age of Electrification Challenges Daring EV Battery Manufacturing & How Players are Responding? An Introduction to the EV Battery Supply Chain The Upstream Challenges and Ethical Considerations in EV Battery Supply Chain The Midstream Dynamics and Strategic Developments in EV Battery Supply Chain The Downstream Developments in EV Battery Manufacturing and Supply Chain Legislative Framework and Ethical Considerations in EV Battery Manufacturing EV Batteries Plant Construction: A Prelude Designing and Constructing EV Battery Plants Construction of EV Gigafactories: Innovation, Safety, and Efficiency Sustainability Challenges in EV Battery Production: Balancing Progress and Environmental Responsibility Global Market Prospects & Outlook High-Octane Rush for Electric Vehicle Battery Plant Construction Projects EV Battery Plant Construction: Mega Enthusiasm for Gigafactories US: The Epicenter of EV Battery Plant Construction with Biggest Boom in Investments Policy Uncertainty Poses as Storm Clouds for New EV Battery Manufacturing Units Companies Embarking on EV Battery Plant Projects to Mitigate Climate Change Will the Breakneck EV Plant Construction Pace Really Meet Lofty Demand Forecasts? EV Battery Plant Construction: Primary Risks with Implications for Project’s Bankability Economic Frontiers: Trends, Trials & Transformations Competitive Scenario Competitive Market Presence – Strong/Active/Niche/Trivial for Players Worldwide in 2025 (E) Recent Market Activity Influencer/Product/Technology Insights

MARKET TRENDS & DRIVERS

The EV Supply Chain: Can the World Break China’s Stranglehold? World Electric Vehicles (EVs) Market by Geographic Region – Annual Sales in Thousand Units for Years 2023 and 2026E China On a Clear Path to EV Battery Dominance Global EV Adoption Propels Demand for Large-Scale Battery Manufacturing Facilities Booming Gigafactory Investments Ignite a New Era for Regional EV Manufacturing Strategic Partnerships Between Automakers and Battery Manufacturers Bode Well for Capacity Expansion of EV Battery Plants Batteries, A Crucial Part of the Supply Chain: Innovations in Battery Is What Will Take EVs to Go Mainstream Effervescent Ongoing Innovations Around EV Batteries to Help Accelerate Performance of EVs & Their Mass Market Adoption in the Coming Decade With EV Commercialization Critically Hinged Onto Cost of Lithium-Ion Batteries, Promised Decline in Battery Costs Strengthens Long-Term Market Outlook Global Demand for Lithium-ion Batteries (In Gigawatt Hours) in Electric Vehicles for the Years 2020, 2023, 2026, 2029 & 2030 Market Prospects for Li-ion Battery Recycling Runs in Parallel to the Demand Outlook for Li-ion Battery Challenges and Solutions in EV Battery Manufacturing: Strengthening the Supply Chain Rising Demand for High-Performance Lithium-Ion Batteries Fuels a Boom in Specialized Manufacturing Facilities North America Ups the Ante on EV Battery Manufacturing South Korean & Japanese Investments in US EV Battery Making Industry Increase with the IRA Coming into Force Even as EV Battery Plants Get an Investment Boost to Meet Projected EV Demand, Fears Grow Over Battery Material Shortages & a Possible Rise in Battery Costs Lithium Demand On an Upward Trajectory Which Battery Technology Will Dominate the EV Battery Market? Next-Generation Battery Chemistries Reshape the Future of EV Manufacturing Facilities Breakthroughs in Battery Technology Drive a Global Surge in EV Battery Plant Construction Emerging Role of Solid-State Battery Technology Sets the Stage for New Manufacturing Lines Recycling is the Only Way to Counter the EV Battery Pollution Threat A Fast Growing Lithium-Ion Battery Recycling Market Means that the Race to Recycling Has Begun, Bringing the Promise of Alleviating Battery Carbon Footprint Government Subsidies and Incentives Drive Growth in Battery Plant Construction The Green Revolution in Battery Manufacturing: How Sustainability is Shaping the Future of Energy Storage Integration of AI in Battery Plant Design Expands Opportunities in Process Optimization Renewable-Powered Battery Plants: Pioneering the Path to Sustainable Energy Storage AI-Driven Predictive Maintenance: Transforming Efficiency in EV Battery Plant Operations Focus on Circular Economy Models Drives Investment in Battery Recycling Plants

FOCUS ON SELECT PLAYERS: Some of the 30 companies featured in this EV Batteries Plant Construction market report include:

ABEL Construction AECOM Barton Malow Bechtel Corporation Clayco Fluor Corporation Gray Construction Company, Inc. Jacobs Kajima Building & Design Group, Inc. LG Corporation

For more information about this report visit

About is the world’s leading source for international market research reports and market data. We provide you with the latest data on international and regional markets, key industries, the top companies, new products and the latest trends.

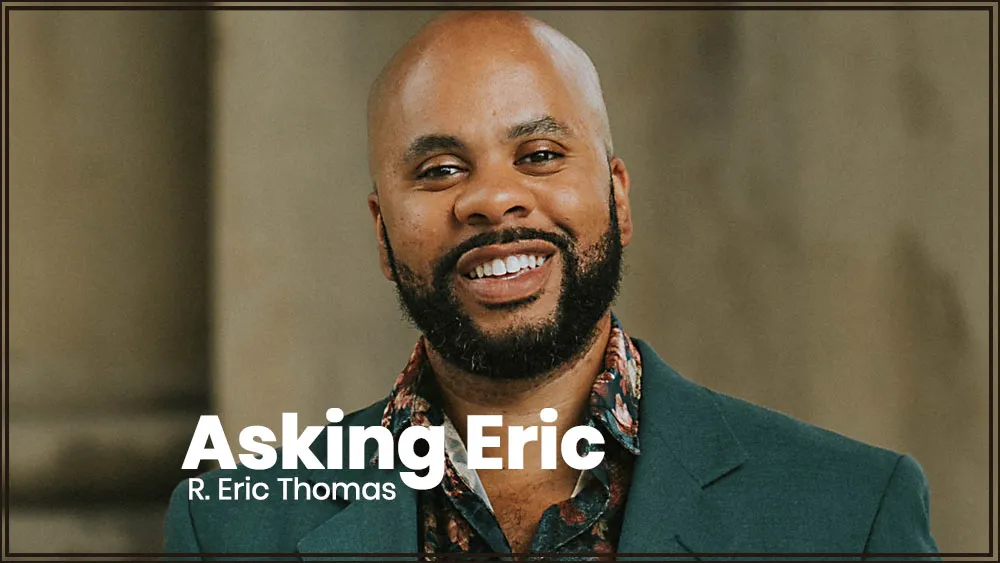

Attachment

EV Batteries Plant Construction Market