Copyright Interesting Engineering

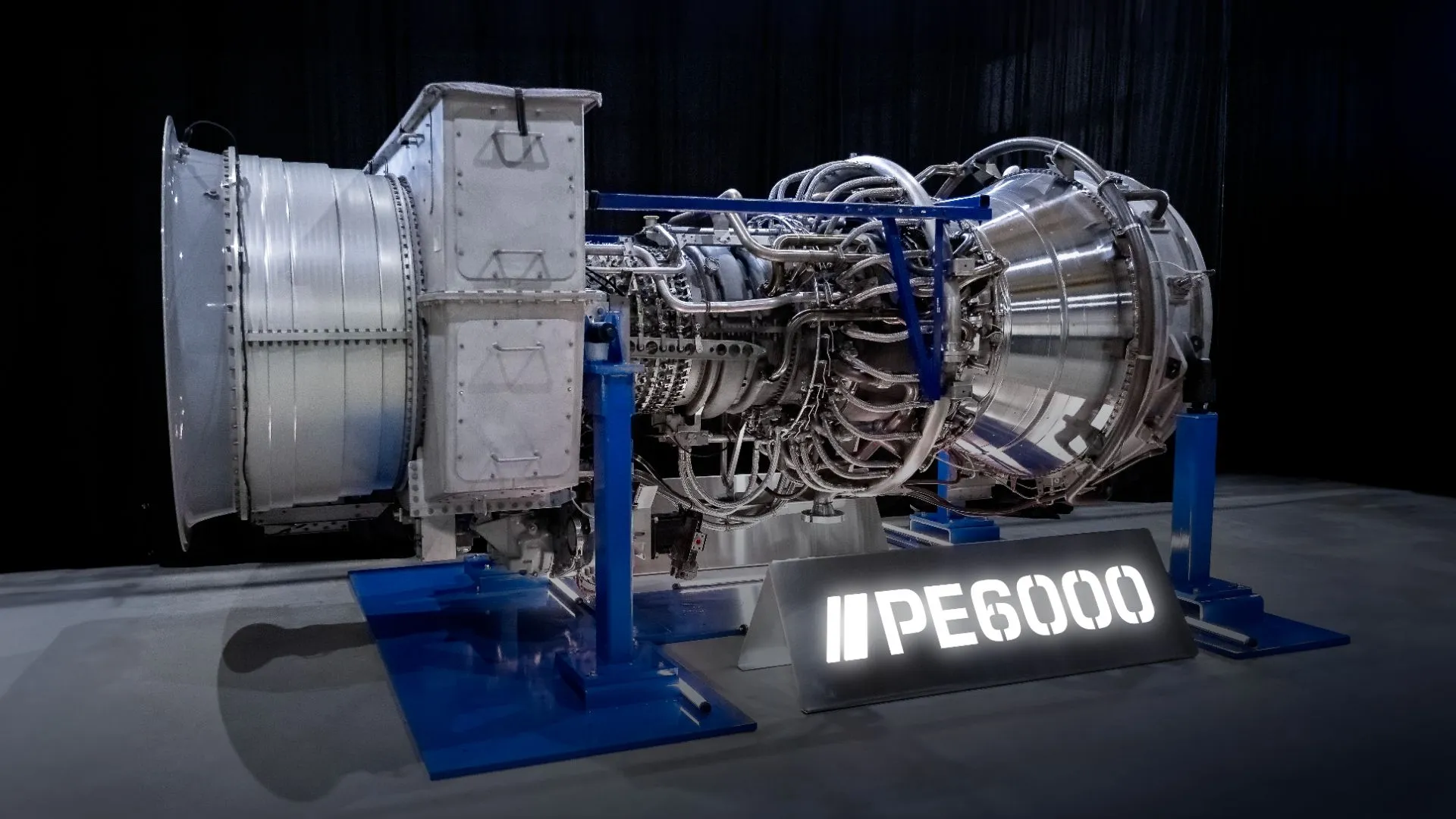

As the world races to build the infrastructure behind artificial intelligence, data centers are hitting a critical energy roadblock. Grid delays and a shortage of new gas turbines are forcing developers to look skyward for answers. Across the U.S. and beyond, old airplane engines are being repurposed into power generators, keeping the AI boom from stalling. Data centers are expanding faster than utilities, with megawatt-hungry facilities waiting years to access grid power. Normally, developers would connect directly to the grid or build dedicated on-site power plants, but the surge in demand has exposed a deep supply shortage. Lead times for new gas turbines from manufacturers like GE, Vernova, and Siemens Energy now stretch from three to five years, sometimes even longer. “There just aren’t enough gas turbines to go around, and the problem is probably going to get worse,” says Paul Browning, CEO of Generative Power Solutions and former head of GE Power & Water and Mitsubishi Power, in an IEEE Spectrum report. Industry research backs this view. Wood Mackenzie notes that lead times for new gas turbines are extending past 2029, while the Institute for Energy Economics and Financial Analysis (IEEFA) reports backlogs of up to eight years for new plants in regions like Southeast Asia. This mismatch between demand and availability has created a new and flourishing market for refurbishing retired aircraft engines into fully functional power generators, known as aeroderivative gas turbines. A second life for jet engines Though the demand is growing, the concept is not new. For decades, companies like GE Vernova and Siemens Energy have converted aviation engines for stationary power generation. The GE LM6000, for instance, is derived from the CF6-80C2 jet engine that once powered commercial aircraft. These “aeroderivative” turbines are lighter, smaller, and easier to maintain than their heavy-frame industrial counterparts, making them ideal for temporary or mobile power setups. At the Data Center World Power show in San Antonio this October, Missouri-based energy firm ProEnergy showcased how it modernizes this approach. The company buys and overhauls used CF6-80C2 engine cores used in GE’s LM6000 and refits them into natural gas turbines branded as PE6000 units. Each refurbished unit can generate up to 48 megawatts (MW) of electricity, enough to power a small-to-medium data center or a town of 20,000 to 40,000 households. Landon Tessmer, Vice President of Commercial Operations at ProEnergy, told IEEE Spectrum that they have sold 21 gas turbines for two data-center projects, amounting to more than 1 gigawatt (GW). He adds, “Both projects are expected to provide bridging power for five to seven years, which is when they expect to have grid interconnection and no longer need permanent behind-the-meter generation.” Bridging power for the AI infra boom These modified engines are an essential bridging technology. A stopgap between the construction of large-scale data centers and their eventual grid connection. According to Tessmer, some facilities use ProEnergy’s turbines to power construction activities and initial operations, after which the units are moved into backup roles or sold to local utilities. Beyond faster delivery times, ProEnergy can supply a unit as early as 2027. Compared to years-long waits from OEMs, the refurbished turbines offer practical advantages. They can start up in five minutes and be swapped out within 72 hours for maintenance. Their emissions, averaging 2.5 parts per million of nitrogen oxide, are well below Environmental Protection Agency (EPA) thresholds, typically ranging from 10 to 25 ppm. Each engine undergoes a painstaking overhaul, where thousands of components are disassembled, cleaned, inspected, and repaired or replaced. The result is a new, custom machine designed for long operational cycles. A short-term fix for a long-term challenge ProEnergy revealed to IEEE Spectrum that since 2020, they have fabricated 75 PE6000 packages, with another 52 being assembled or on order. Originally aimed at helping utilities meet peak power demands, the technology has found a new and booming market in data centers. Tessmer has even seen permitting delays for new grid connections stretch to eight or even ten years in some cases. With AI infrastructure scaling at an unprecedented rate, these repurposed engines, once symbols of aviation’s golden age, quietly keep the digital world alive on the ground. As the global turbine shortage deepens, their second act as power generators may prove vital in sustaining the momentum of the AI revolution.