Copyright Interesting Engineering

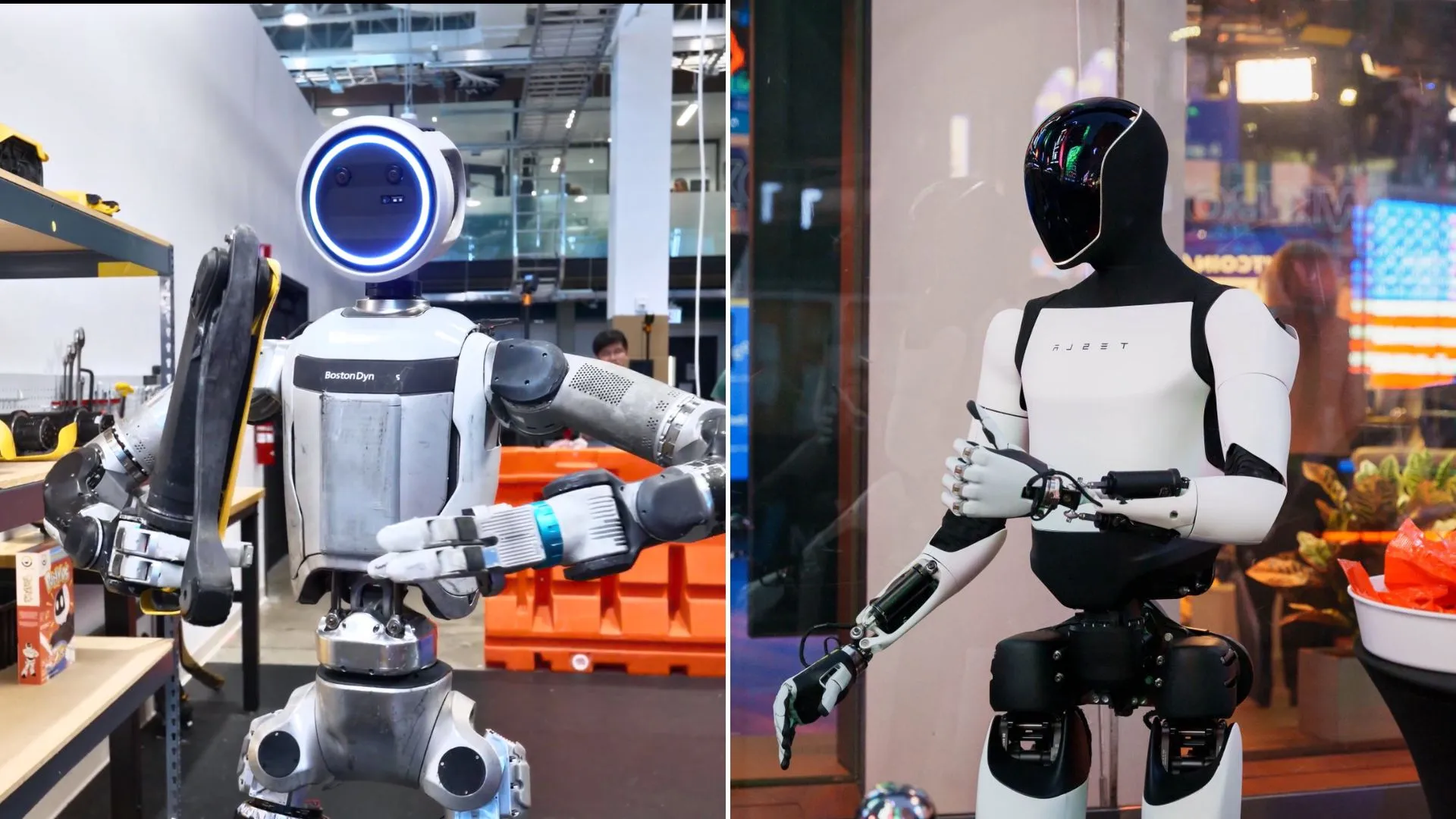

In the quest to make machines walk, think, and work like us, humanoid robots have become the ultimate measure of progress in modern engineering. Among them, Boston Dynamics’ Atlas and Tesla’s Optimus represent two opposing philosophies. One chases agility and research breakthroughs, the other aims for affordability and everyday utility. The differences are not just marketing. They show up in hardware choices, software priorities, recent demonstrations, and the companies’ near-term plans. Design philosophies and goals Boston Dynamics frames Atlas as a research vehicle for “whole-body mobility” and dynamic control. A platform to discover new locomotion and manipulation strategies rather than a product aimed immediately at factories or households. That focus explains the emphasis on speed, balance, and extreme agility in its public demonstrations. Tesla frames Optimus the opposite way. A general-purpose, bi-pedal robot meant to take on “unsafe, repetitive or boring” work by leveraging Tesla’s AI and manufacturing scale. The two roadmaps, therefore, pull in different directions. Atlas toward pushing control boundaries and Optimus toward integration with production-line economics and perception stacks adapted from autonomous driving. That said, the story is evolving. Boston Dynamics, after transitioning Atlas into a fully electric version, is actively piloting commercial deployment with its industry partner, Hyundai Motor Company, with factory use cases in automotive manufacturing already identified. On the Optimus side, Tesla has reported deploying at least two Optimus units performing tasks in its factory environment and announced pilot production lines at its Fremont facility, marking the first steps toward internal integration. Athleticism and demonstrable feats Atlas’s public record is built on audacious motion. The robot’s parkour and backflip videos, milestones reached through iterative control research over the years, are not just theatrical stunts but experiments in dynamic balance, state estimation, and whole-body coordination. Those demonstrations, first widely circulated in 2018 and reinforced in subsequent releases, show Atlas navigating uneven terrain, leaping, bounding, and performing coordinated obstacle navigation that few bipeds have matched even today. In April 2024, Boston Dynamics explicitly repositioned Atlas as an all-electric machine, while maintaining athleticism at the core of its mission. These feats signal what is physically possible for humanoids when power density and control are prioritized. Optimus’s public demonstrations have been more conservative and directed toward tasks humans recognize as useful. Walking on a stage, picking up and handling an egg without breaking it, folding a shirt, and sorting small objects. Tesla has repeatedly shown short clips of coordinated motions, and, increasingly, choreographed group routines, while emphasizing that the robot’s learning and perception stacks borrow from the company’s autonomous-vehicle neural networks. Observers have noted that many videos either rely on teleoperation or heavy supervision during lab trials. Tesla has also utilized motion capture to collect data on human movement, thereby accelerating the training of motion primitives. Those demonstrations suggest incremental competence in manipulation and perception, rather than the extreme agility emphasized by Atlas. Hardware and actuation: power vs. practicality Actuation choices reflect priorities. Atlas, historically hydraulic for its high torque and rapid force delivery, has transitioned to fully electric actuation in its latest iteration to improve efficiency and maintainability while preserving dynamic capability. Boston Dynamics’ engineering notes highlight that the platform is tuned for performance over economy. Optimus is designed from the ground up to be all-electric and lighter, with an emphasis on manufacturability, energy efficiency, and reduced noise. Tradeoffs that favor continuous, lower-force tasks in civilian settings rather than explosive athletic motions. While Atlas’s hardware is optimized for peak physical performance, Optimus’s hardware is optimized for cost, reliability, and integration into production environments. Software and perception: specialized control versus scaled neural systems Atlas research emphasizes real-time control loops, model-based balancing, and motion planners that can utilize high-bandwidth actuators to recover from disturbances and execute acrobatics. Boston Dynamics couples perception (IMUs, cameras, possibly LiDAR) with these controllers to enable rapid reflexive responses. Tesla’s approach leans heavily on large-scale data, neural networks, and perception models honed on millions of driving hours. The idea is to transfer vehicle-grade vision and scene understanding into a body that can manipulate and navigate human environments. That strategy favors generalization from data and repeated tasks, but it also places enormous dependence on data quantity, sim-to-real pipelines, and strong safety layers before unsupervised operation in the field. Measurable specs and current limits The most recent version of Atlas by Boston Dynamics is described as a fully electric humanoid robot designed for mobility, dexterity, and agility. According to secondary sources, it stands about 1.5 m tall, weighs approximately 89 kg, and features about 28 degrees of freedom (DoF). It is capable of sprinting at speeds up to roughly 2.5 m/s and is equipped with LiDAR plus stereo-vision sensors for navigation. Meanwhile, the Optimus robot from Tesla, Inc. is reported to stand about 1.73 m (5 ft 8 in) and weigh around 57 kg (125 lb). It is designed to carry up to 20 kg (45 lb) while walking and to lift or dead-lift up to approximately 68 kg (150 lb). One source also lists up to 40 structural actuators/DoF in the full body. Both Atlas and Optimus remain evolving platforms, each advancing toward distinct long-term goals. Tesla is progressing Optimus from its early prototypes to the Generation 3 model, featuring redesigned hands, lighter actuators, and smoother motion. Commercial deployment and trajectories Viral videos or factory pilots won’t define the next phase for humanoid robots, but by the time they start contributing measurable economic value. For Atlas, this means proving that a highly agile, fully electric system can perform sustained, repetitive work without the trade-offs that come with research-grade complexity. For Optimus, it’s about scaling from supervised, task-specific units to autonomous, reliable workers that can adapt to new tasks with minimal retraining. The next milestone will be reached when either platform demonstrates consistent uptime, efficient maintenance, and safe human collaboration over extended operational cycles. The benchmarks that separate a showcase prototype from a functional coworker. Boston Dynamics brings years of control and motion expertise into industrial reality, while Tesla injects the discipline of scalable manufacturing and neural-network training into robotics. Together, they are closing the gap between mechanical dexterity and economic utility, demonstrating that humanoid robots are no longer mere lab experiments but emerging assets that will actively contribute to development.