Copyright Wccftech

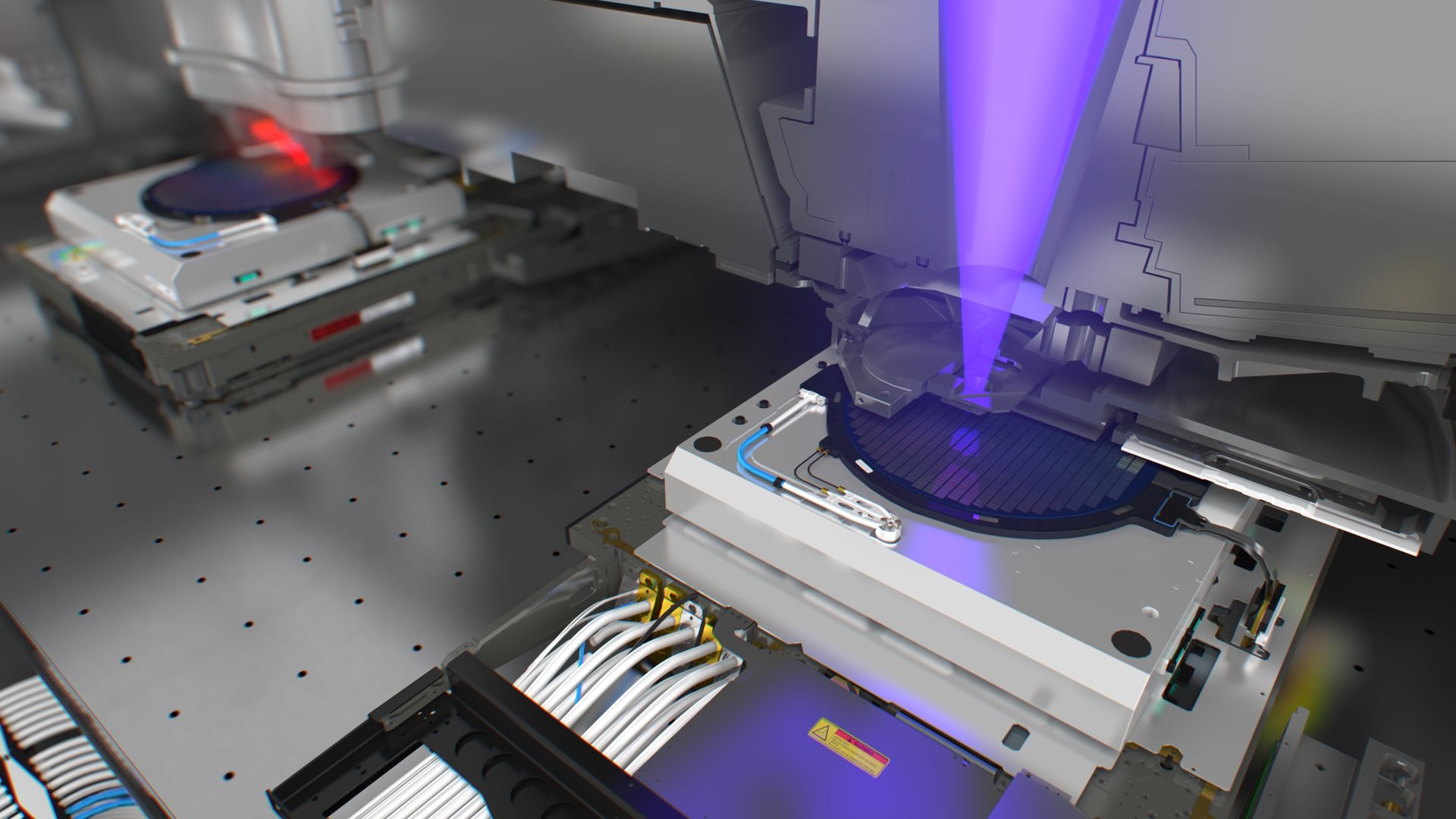

Well, the pursuit of a lithography breakthrough, Chinese engineers reportedly managed to 'break' ASML's DUV equipment, and actually called out the Dutch firm to sort out the problem. The Chinese semiconductor industry faces a critical barrier in scaling up chip production, primarily due to the lack of lithography equipment in fabs. This limitation has confined firms like SMIC to a specific production volume and prevented them from scaling up significantly for several years now. Apart from developing in-house alternatives, it seems like Chinese engineers were actually keen to 'reverse engineer' ASML's DUV equipment, according to a report from The National Interest. Now, in the process of opening up the equipment, the individuals broke down the DUV machinery. Interestingly, a source reports that in recent months, the Chinese have been caught trying to reverse-engineer the ASML DUV lithography machine. But in the process of disassembling one of their older ASML systems, the Chinese apparently damaged it, prompting them to call ASML to send assistance to repair the broken device. Once ASML technicians arrived in China, they soon discovered that the machine had not simply broken down, but had broken because the Chinese attempted to disassemble and reassemble it. This is actually interesting and hilarious at the same time. While the report doesn't pinpoint the specific source of this development, the occasion doesn't seem too far-fetched, considering China's 'hunger' for a breakthrough in the chip industry. Now, once the machines broke down, Chinese engineers actually called out ASML to fix the machines, but the Dutch firm discovered the intentions of the engineers involved. The report has yet to be verified by ASML for now. Now, reverse engineering a DUV machine is a pretty complex task, considering that it involves dealing with high-precision subsystems, along with fragile equipment. ASML is one of the most advanced out there when it comes to producing lithography equipment, which is why 'decoding' the internal technology isn't as easy as it may seem. More importantly, the machine is also aware of calibration baselines, the test routines, and the replacement parts onboard, which is why ASML becomes the sole entity to deal with such equipment. China has made advancements when it comes to building domestic lithography tools, but they have still fell short, and haven't reached to a point where they can replicate the quality brought in by the Dutch firm.