Copyright Interesting Engineering

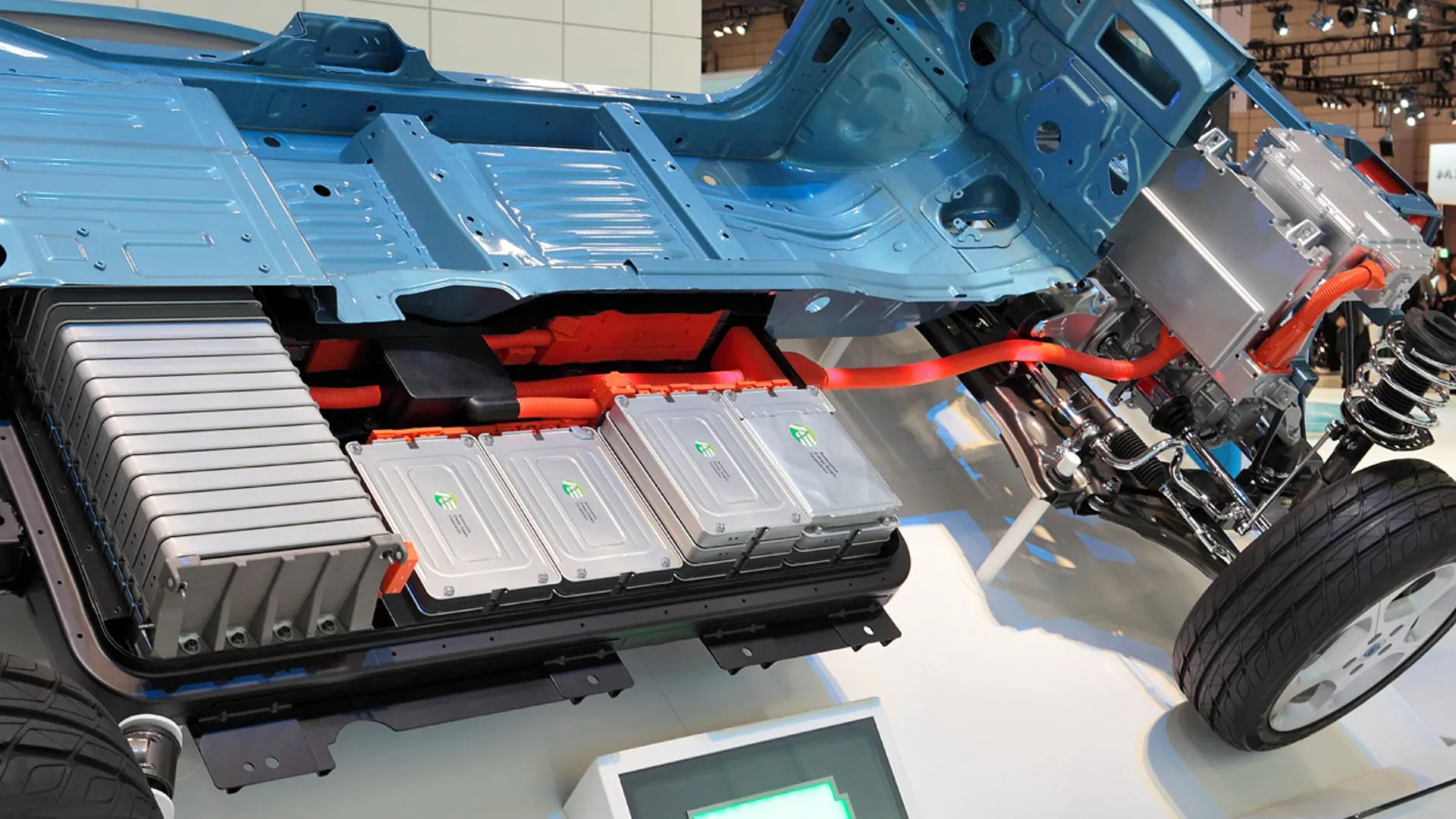

The surge in electric vehicles has brought with it a growing pile of retired lithium-ion batteries that are difficult and costly to recycle. While these batteries still contain valuable metals like nickel, cobalt, and lithium, most recycling techniques destroy the very structure that made them efficient in the first place. A team from Huazhong University of Science and Technology now claims to have found a better way that restores, rather than rebuilds, the material inside. Their molten salt-based method directly regenerates degraded battery cathodes, allowing them to recover their performance and structure with minimal waste. Traditional recycling usually extracts metals from spent batteries through chemical or thermal processes. The metals can then be reused, but the intricate atomic arrangement that once enabled high-energy storage is lost in the process. “Traditional recycling can recover metals, but it cannot bring back the original atomic structure of the material,” said corresponding author Yang Yang. “Our method allows the degraded cathode to be reborn, regaining its crystal order and high capacity.” The researchers focused on a material known as NCM811, or LiNi₀.₈Co₀.₁Mn₀.₁O₂, a staple in modern electric vehicle batteries due to its high energy density. Over years of charging and discharging, NCM811 loses lithium and develops defects that weaken its performance. To counter this, the team used a ternary molten salt made of lithium hydroxide, lithium nitrate, and lithium salicylate. When heated, the molten salt turns into a liquid medium that allows lithium ions to flow freely. These ions penetrate the damaged material, repairing defects while helping atoms return to their original, ordered structure. Restored structure and performance Microscopic analysis revealed that the repaired cathodes regained a uniform, single-crystal structure, with the unwanted “rock salt” surface layer completely removed. The rejuvenated material showed an initial discharge capacity of 196 milliamp hours per gram and retained 76 percent of that capacity after 200 charge–discharge cycles, surpassing most current recycling results. “This process effectively heals the internal and surface damage of the cathode material,” said first author Fangshu He. “It not only replaces the lost lithium but also restores the ordered layered structure that is key to long battery life.” Because the molten salt process works at lower temperatures and avoids harsh acids or toxic solvents, it significantly reduces both energy use and environmental impact. The team says this approach could form the foundation for a closed-loop system in which used batteries are directly converted into high-quality materials for new ones. Toward scalable green recycling The researchers acknowledge that their work is still in the laboratory stage. They plan to optimize the process for industrial-scale production and conduct a full life-cycle analysis to assess environmental performance and cost-effectiveness. If scaled successfully, the molten salt method could help address one of the biggest sustainability challenges in electric mobility of what to do with used batteries. By reviving old cathodes instead of breaking them apart, the process could make battery recycling both cleaner and more circular.