By Alexia Hope

Copyright researchsnipers

In industries such as mining, construction, agriculture, and logistics, the movement of bulk materials is an essential operation. Conveyor systems form the backbone of these industries, allowing efficient transportation of ores, aggregates, grains, and other heavy loads across significant distances. At the heart of every conveyor system lies a critical component: conveyor pulleys. These heavy-duty components play a vital role in ensuring smooth operations, reducing downtime, and maximising productivity in bulk material handling.

This article explores the function of conveyor pulleys, their different types, and their importance in supporting heavy-duty applications.

What Are Conveyor Pulleys?

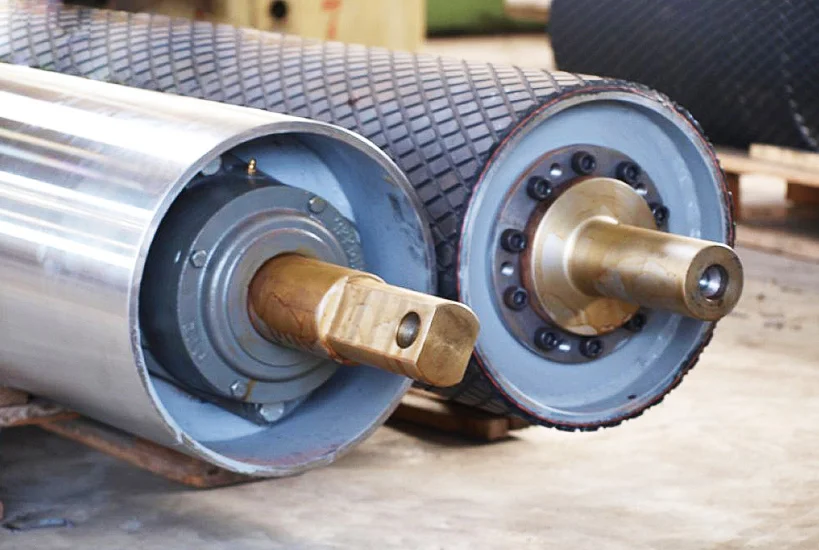

Conveyor pulleys are cylindrical components that provide the driving and redirecting force to conveyor belts. They transmit mechanical power and tension, enabling the belt to carry materials from one point to another. Heavy-duty pulleys are specifically engineered to withstand high loads, extreme conditions, and continuous operation.

A typical pulley consists of a shaft, end discs, locking elements, and a shell. Together, these elements allow pulleys to handle stress, maintain belt alignment, and distribute load effectively across the conveyor system.

Types of Conveyor Pulleys

There are several types of conveyor pulleys, each designed for a specific function in bulk material handling systems:

Head Pulley – Located at the discharge point of the conveyor, this pulley drives the belt and moves material forward.Tail Pulley – Positioned at the opposite end, it redirects the belt back toward the drive pulley.Snub Pulley – Used to increase the wrap angle of the belt around the drive pulley, improving traction.Bend Pulley – Changes the direction of the belt in specific conveyor layouts.Take-Up Pulley – Maintains tension in the conveyor belt, ensuring consistent operation.

Each type of pulley plays a distinct role in supporting efficient, reliable material handling.

Why Heavy-Duty Conveyor Pulleys Are Essential

In bulk material handling, systems are often required to carry thousands of tonnes per hour in challenging conditions. Standard pulleys may not withstand these demands, which is why heavy-duty conveyor pulleys are indispensable. Their benefits include:

Durability – Built with high-strength steel and reinforced welds to handle intense loads.Reduced Downtime – Designed to resist wear and tear, reducing maintenance needs.Energy Efficiency – Properly designed pulleys reduce slippage and energy loss.Belt Protection – Heavy-duty pulleys maintain belt alignment, preventing costly damage.Long Service Life – Enhanced engineering and design ensure longer operational cycles.

By investing in robust pulleys, industries can maintain reliable systems that keep operations running smoothly.

Conveyor Pulleys in Bulk Material Handling Systems

Bulk material handling requires systems that can transport abrasive, heavy, and sometimes wet materials efficiently. Conveyor pulleys are central to this process, providing the power and stability necessary for continuous flow.

For example, in the mining industry, pulleys are required to handle high-tension belts transporting ore from deep underground to the surface. In agriculture, pulleys must endure long hours moving grain, feed, or fertilizer across processing facilities. Similarly, in construction, pulleys enable the movement of aggregates and cement through rugged environments.

These applications highlight how essential pulleys are for meeting production demands and ensuring smooth supply chain operations.

Materials and Design Considerations

The effectiveness of heavy-duty conveyor pulleys depends largely on their design and construction materials. Important factors include:

Shell Thickness – Determines the strength and resistance to deformation.Lagging – Rubber or ceramic lagging improves grip, reduces slippage, and protects the pulley surface.Bearings – High-quality bearings enhance efficiency and extend the service life of pulleys.Weld Integrity – Precision welding ensures pulleys can withstand heavy stresses without failure.Shaft Design – Must be engineered to endure both radial and axial loads.

Proper design ensures pulleys can handle high torque and maintain alignment under extreme conditions.

Innovations in Conveyor Pulley Technology

Modern engineering has introduced several innovations to improve pulley performance, such as:

Finite Element Analysis (FEA) to test durability under simulated stress.Advanced lagging materials that improve grip and extend pulley life.Smart monitoring systems that detect wear, vibration, or misalignment before failures occur.Customised pulley designs for unique bulk handling environments.

These innovations are helping industries reduce operational costs while improving safety and efficiency.

Maintenance and Best Practices

Even the most durable pulleys require regular inspection and maintenance. Best practices include:

Routine Inspections – Checking for cracks, wear, or misalignment.Lubrication – Ensuring bearings are properly greased to avoid overheating.Lagging Replacement – Monitoring lagging wear and replacing when traction is compromised.Alignment Checks – Preventing belt tracking issues that lead to premature wear.

Adhering to these practices maximises the lifespan of both the pulleys and the conveyor system.

Wrapping Up: Why Conveyor Pulleys Matter

Heavy-duty conveyor pulleys are the unsung heroes of bulk material handling systems. They provide the strength, stability, and reliability needed to move massive quantities of material in industries like mining, construction, and agriculture. By investing in durable, well-designed pulleys and maintaining them properly, companies can improve efficiency, minimise downtime, and extend the lifespan of their conveyor systems.

Industry leaders such as PROK continue to innovate in pulley design and manufacturing, offering solutions that deliver higher performance, greater durability, and smarter monitoring options for bulk material handling. Their advancements ensure that conveyor systems can meet today’s demanding operational requirements while remaining cost-effective and reliable.

As bulk material handling continues to evolve with automation and smart technologies, conveyor pulleys will remain at the core of efficient and sustainable operations.