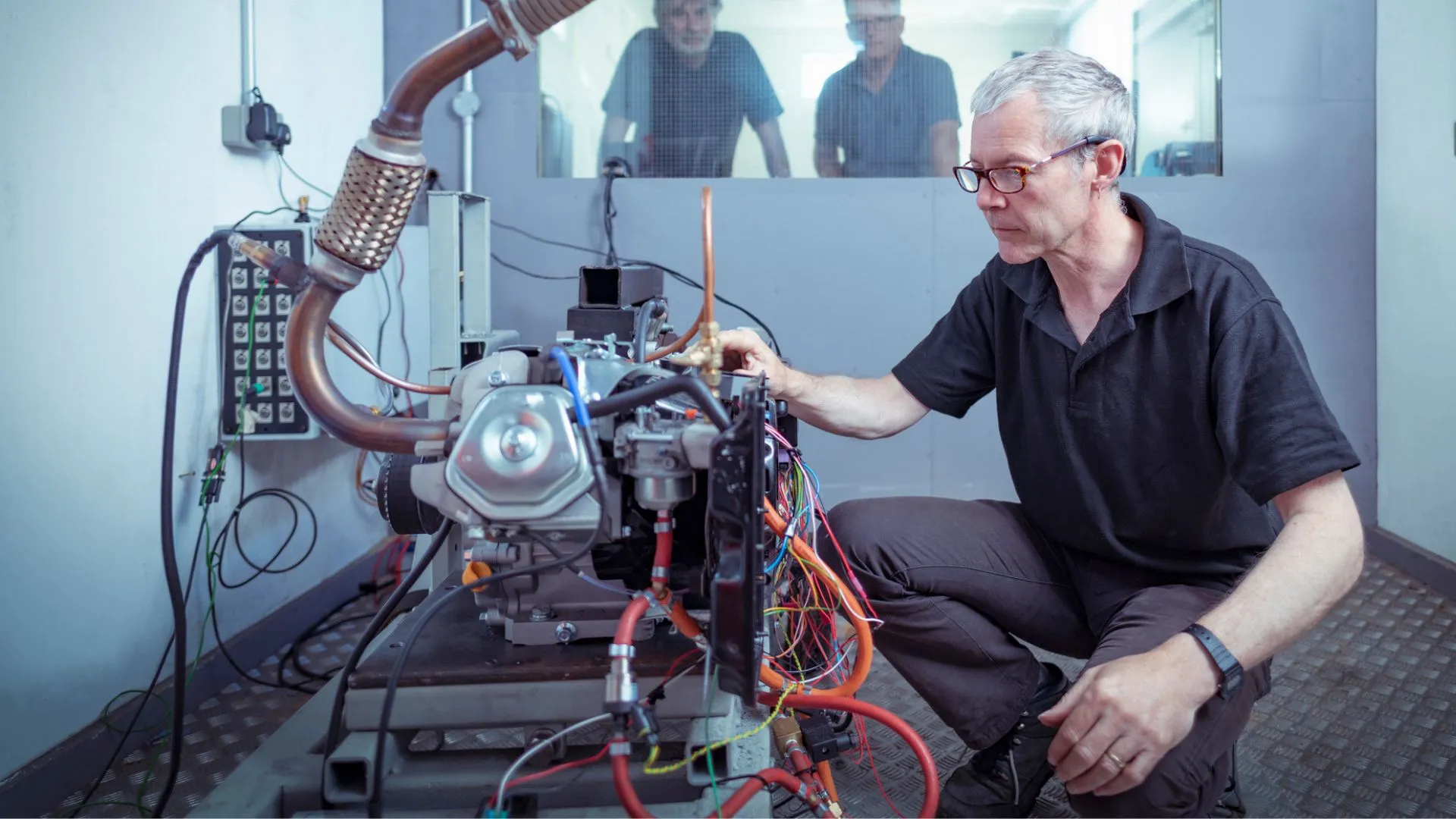

Researchers in Japan have developed an inexpensive, high-performance catalyst for hydrogen storage using a modified form of ‘green rust,’ a common iron hydroxide mineral.

The work, conducted at the National Institute for Materials Science (NIMS), demonstrates a method to release hydrogen from sodium borohydride (NaBH4) without relying on costly precious metals like platinum. This addresses a key obstacle in the use of hydrogen as a clean fuel.

“We expect that our catalyst will be used for hydrogen fuel cells in many onboard applications like cars and ships,” said Dr. Yusuke Ide, who led the research team.

“This will hopefully lead to various forms of emission-free mobility.”

Using sodium borohydride as alternative

Hydrogen is considered an efficient and environmentally friendly energy carrier. A primary difficulty in its widespread use is the development of safe and practical storage methods.

While solid-state materials can store hydrogen, many require high temperatures for its release, creating practical limitations.

Sodium borohydride is an alternative that generates hydrogen through hydrolysis—a reaction with water—at room temperature.

However, this process requires a catalyst. The high cost of traditional catalysts, such as platinum, has limited the economic viability of this technology for large-scale applications.

“Although sodium borohydride has been investigated extensively as a high-capacity hydrogen-storage material that can be used to move toward a hydrogen-powered society, the development of efficient and cost-effective catalysts for the generation of hydrogen from SBH remains challenging,” explained the researchers in a new study.

Presenting a cost-effective solution

The research team has presented a cost-effective solution. They modified green rust, a material previously considered too unstable, by treating its particles with a copper chloride solution.

This treatment forms nanoscale copper oxide clusters at the edges of the particles, creating highly active sites for hydrogen production.

“Green rust is a mixed-valent iron hydroxide mineral that belongs to a structural family of layered double hydroxides comprising positively charged ferrous/ferric iron hydroxide-based layers and interlayer anions,” highlighted the study.

The catalyst also utilizes solar energy. The green rust structure absorbs sunlight, and the energy is transferred through the copper clusters, which enhances the efficiency of the hydrolysis reaction and increases the rate of hydrogen generation.

“Performance tests revealed that the new catalyst achieves a high turnover frequency for hydrogen production comparable to or even exceeding those of traditional precious metal-based materials,” remarked the researchers in a press release.

“It also showed excellent durability, maintaining catalytic activity through repeated use.”

Practical implications

The practical implications of this research are notable. The catalyst operates effectively at room temperature, is relatively simple to produce, and could be integrated into existing hydrogen systems.

Combined with ongoing efforts to develop low-cost production of sodium borohydride, this advance in catalyst technology could support the broader adoption of clean hydrogen energy.