Microsoft has announced a breakthrough in cooling technology that could reshape the future of artificial intelligence hardware. The company successfully tested microfluidic cooling, a system that channels liquid directly inside a chip to remove heat.

Early results show it can outperform today’s advanced cold plate systems by as much as three times.

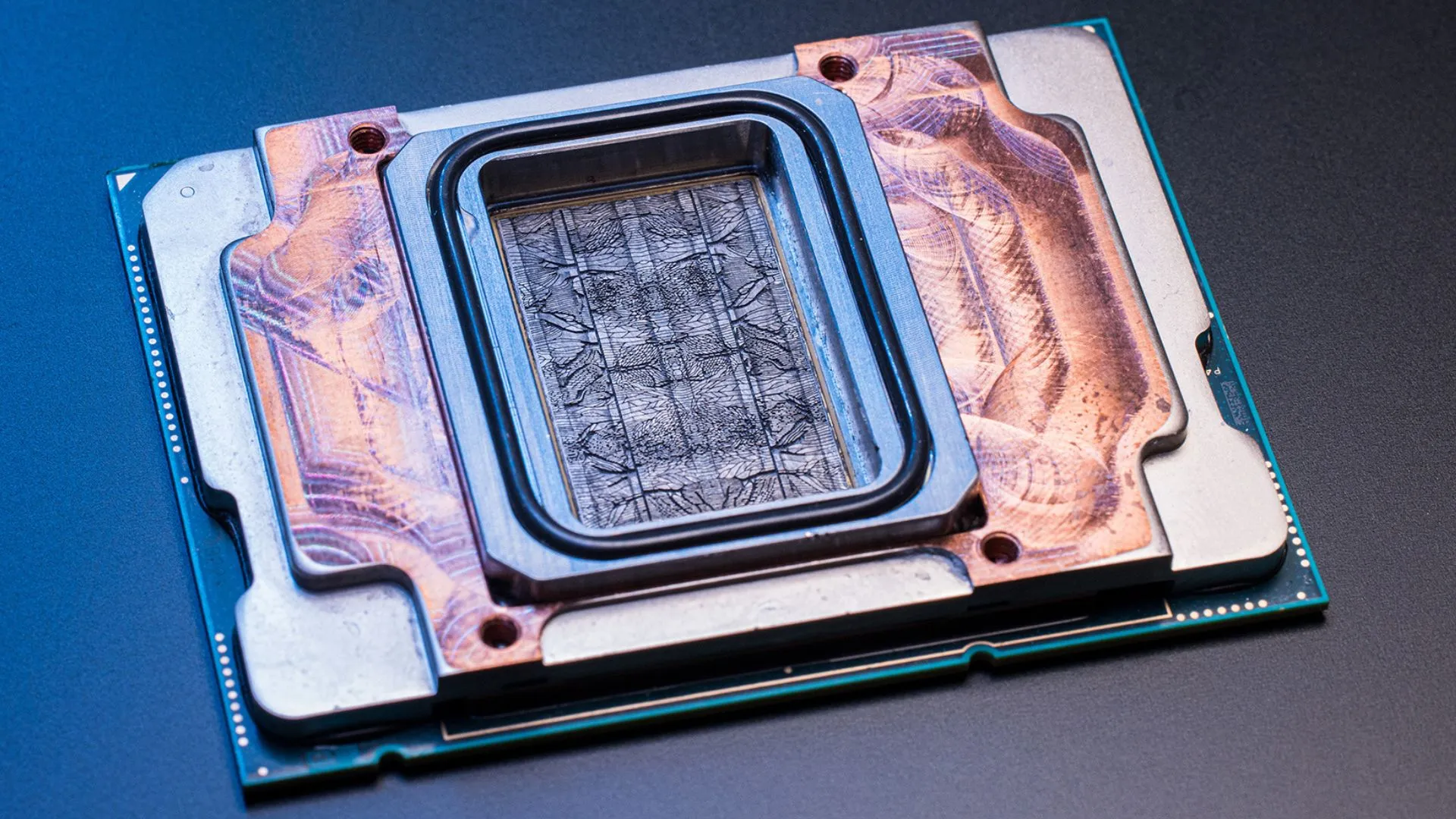

AI chips are growing hotter with each generation. Current systems like cold plates sit on top of chips but remain separated by layers that limit efficiency.

Microsoft’s new approach carves hair-thin grooves into the back of a chip, allowing liquid coolant to flow directly across the silicon.

This direct contact removes heat far more effectively.

The team also applied AI to detect unique heat signatures and direct cooling liquid where it was most needed.

According to Microsoft, this reduced the maximum temperature rise of a GPU by up to 65 percent.

“If you’re still relying heavily on traditional cold plate technology, you’re stuck,” said Sashi Majety, senior technical program manager for Cloud Operations and Innovation.

Microsoft proved the design by cooling a server running simulated Teams meetings. “Microfluidics would allow for more power-dense designs that will enable more features that customers care about and give better performance in a smaller amount of space,” said Judy Priest, corporate vice president and chief technical officer of Cloud Operations and Innovation.

She added that the next priority was to test reliability. “But we needed to prove the technology and the design worked, and then the very next thing I wanted to do was test reliability,” Priest said.

Inspired by nature

To perfect the design, Microsoft worked with Swiss startup Corintis. Together, they used AI to shape bio-inspired channels that mimic the veins of a leaf. These designs cooled hot spots better than traditional straight channels.

“Systems thinking is crucial when developing a technology like microfluidics. You need to understand systems interactions across silicon, coolant, server and the datacenter to make the most of it,” said Husam Alissa, director of systems technology in Cloud Operations and Innovation.

Bigger role in datacenters

Microfluidics could have broad impact beyond individual chips. “Hardware is the foundation of our services,” said Jim Kleewein, technical fellow, Microsoft 365 Core Management. “We all have a vested interest in that foundation – how reliable it is, how cost effective, how fast, how consistent the behavior we can get from it, and how sustainable, to name just a few. Microfluidics improves each of those: cost, reliability, speed, consistency of behavior, sustainability.”

By cooling chips more efficiently, Microsoft expects to reduce datacenter energy use and costs. The approach could also allow servers to run hotter workloads, including overclocked chips, without damage. Denser server racks would become possible, cutting the need for new buildings.

Looking ahead, Microsoft sees microfluidics enabling 3D chip designs that stack layers of silicon.

“Anytime we can do things more efficiently and simplify this opens up the opportunity for new innovation where we could look at new chip architectures,” Priest said.

Kleewein said Microsoft wants microfluidics to spread across the industry. “We want microfluidics to become something everybody does, not just something we do,” he said.