A new German startup has recently come up with a groundbreaking way to turn industrial waste into high-value, sustainable materials, by using a yeast-like black fungus.

Biotech startup Biophelion has recently developed biotechnological processes that convert carbon-rich industrial byproducts into recyclable platform chemicals.

The Jena-based company was founded as a spin-off from the Leibniz Institute for Natural Product Research and Infection Biology (Leibniz-HKI). It was prompted by the ‘Circular Biomanufacturing Challenge’ organized by the Federal Agency for Breakthrough Innovations, SPRIND.

Their process could potentially decarbonize the chemical industry, which is widely regarded as one of the most polluting sectors around the world. The industry is responsible for about 5 percent of global CO2 emissions.

“SPRIND has given us momentum – in content, finance, and strategy,” Lara Regestein, Biophelion’s future CEO, revealed.

A fungus with industrial potential

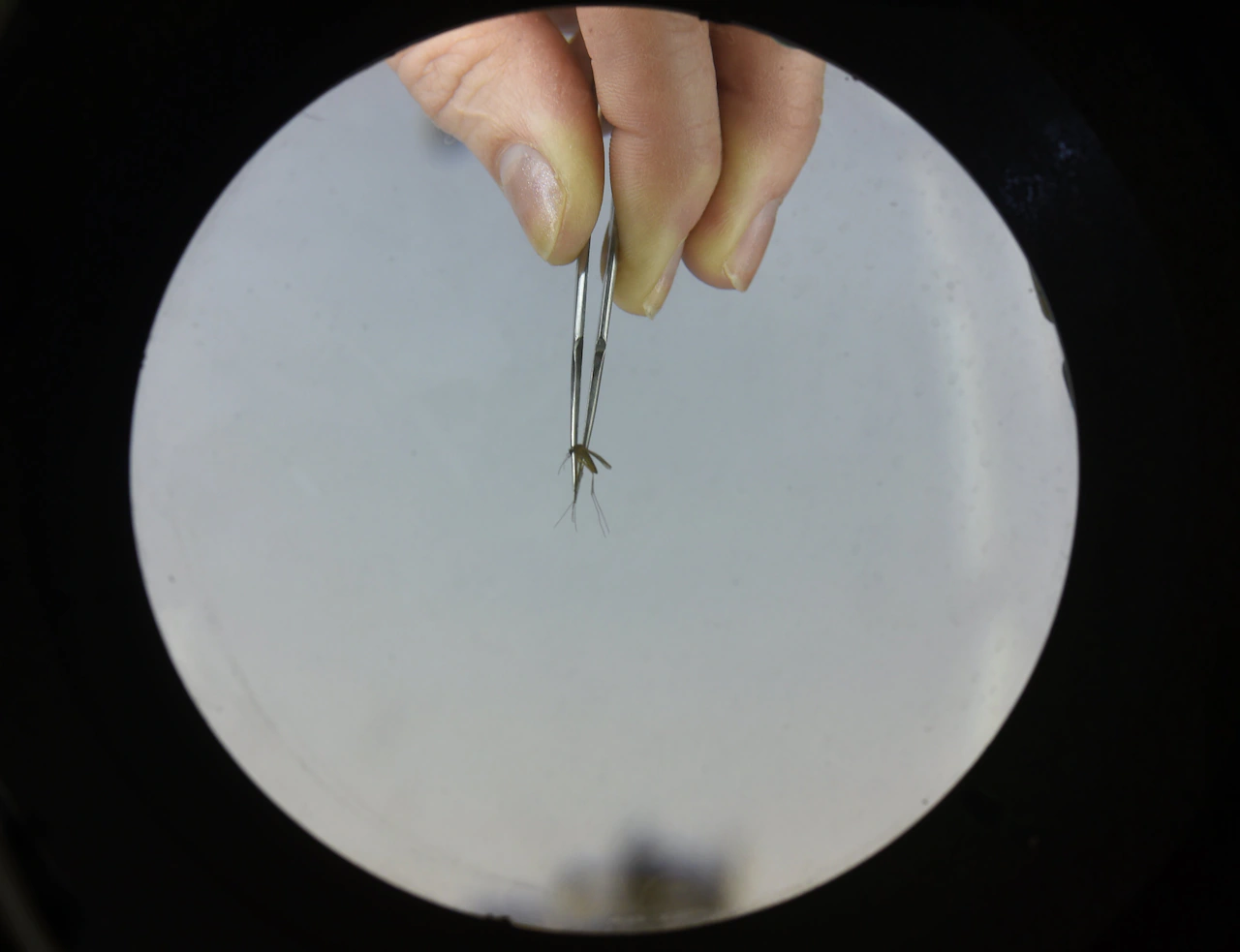

The innovative process harnesses the extraordinary metabolic flexibility of a black yeast-like fungus to convert industrial waste into valuable materials. Black yeast-like fungi are unique because many inhabit strange, extreme, poor, or toxic environments.

The fungus is reportedly capable of breaking down carbon-rich waste streams produced in large volumes during bioethanol production, sugar processing, and paper manufacturing.

Instead of allowing the embedded carbon to escape into the atmosphere as CO2, the microorganism transforms it into useful compounds, thus closing the carbon loop and turning pollution into production.

According to Biophelion, the black yeast produces three crucial compounds from waste materials. These include a bio-based polyester for future packaging, the edible polymer pullulan already used in food, as well as a novel surfactant still under investigation.

Unlike traditional chemical processes, which often require high energy input and generate harmful byproducts, the startup’s biotechnological approach is designed to be clean, efficient, and circular.

“Biophelion is specifically developing applications that are not yet conceivable today – we are breaking new ground with pullulan and our surfactant molecule in particular,” Till Tiso, one of the startup’s founders and future CTO, stated.

Rethinking plastic

Instead of focusing on just existing applications, the startup is currently exploring new uses for its materials. At the moment, they are investigating if they could use pullulan as a 3D printing material.

As such, it would potentially replace petroleum-based plastics in fast-growing additive manufacturing sectors. In the long term, the team imagines producing 3D-printed bioreactors for the circular bioeconomy from pullulan. This would allow the fungus to produce the final product and its own production environment.

Surfactants, on the other hand, are mass-produced and widely used in detergents and dishwashing liquids. They frequently end up in wastewater and pollute the environment. This is why biologically produced and therefore easily degradable alternatives are an important contribution to reducing the ecological footprint.

The startup is based at the BioInstruments Center on the Beutenberg Campus in Jena, steps away from Leibniz-HKI. The proximity to the institute will enable close scientific collaboration as the company scales its operations and continues optimizing the fungus-based processes.

“Leibniz-HKI is delighted to be able to continue accompanying and supporting the two founders as a participating institution in the future,” Axel Brakhage, PhD, Leibniz-HKI director, said in a press release.

He highlighted that the team brings outstanding scientific expertise and showed great courage in launching the company. “We now wish the newly appointed managing directors every success with Biophelion,” he concluded.