By Stephen Chen

Copyright scmp

Following several high-profile aeronautical production quality lapses in recent years, including a door falling off mid-flight and tooling left inside aircraft, the last thing any plane manufacturer wants is a missing bolt or any oversight that slips through manual checks.

Enter the futuristic assembly line of C919, China’s first domestically developed large passenger jet.

Leveraging a groundbreaking 5G-enabled industrial network system, the C919 smart mega factory in Shanghai is setting a new standard for aircraft manufacturing integrity, ensuring that all the parts, tools and technicians are monitored in real time.

At the heart of this powerful surveillance system is a “field-level” industrial network developed by researchers at Shanghai Jiao Tong University in collaboration with Comac (Commercial Aircraft Corporation of China).

This network integrates 5G wireless connectivity with time-sensitive networking to create a hybrid communication backbone that connects every sensor, robot, tool and worker across the final assembly line, according to a study published in the peer-reviewed journal Acta Automatica Sinica in August.

Unlike conventional factory networks that separate data collection, communication and control, the Chinese system unifies them into a single, intelligent loop – a concept known as sensing-transmission-control integration.

This allows for millisecond-level responsiveness and ensures that any deviation from standard procedures is detected and flagged immediately.

“It is a world first,” wrote the team led by Professor Guan Xinping of Shanghai Jiao Tong University.

One of the most critical applications of this system is in tool and parts tracking. In traditional aircraft assembly, tools can be misplaced, often due to human error or fatigue.

This follows a terrifying mid-air incident in 2024 in which a door plug on an Alaska Airlines Boeing 737-9 MAX blew out mid-flight due to missing bolts, just minutes after the California-bound jet took off from Portland, Oregon.

It caused depressurisation of the aircraft, with items being sucked out of the cabin. Several passengers were injured and the plane was forced to make an emergency landing.

After the incident, investigators found that manual inspection logs did not match the actual work performed.

The C919 factory combats this with a network of wireless sensors and smart tool cabinets.

Using 5G’s ultra-reliable low-latency communication or uRLLC, the system tracks each tool’s location throughout the assembly process. If a technician fails to follow the book, the system triggers an alert.

With the support of the new network architecture, industrial devices on the shop floor are now highly interconnected, creating a tightly linked “sense-transmit-control” closed-loop system, according to Guan and his colleagues.

But this brings two major challenges.

“Rapidly changing production tasks cause sudden shifts in resource needs, but the available communication and computing resources are fixed and inflexible, leading to a mismatch,” Guan’s team wrote.

“The data coming from different sources vary greatly in timing and space, making it difficult to accurately estimate the overall system state.

“We have constructed a systematic solution through theoretical innovation, technological breakthroughs and real-life applications,” the researchers added.

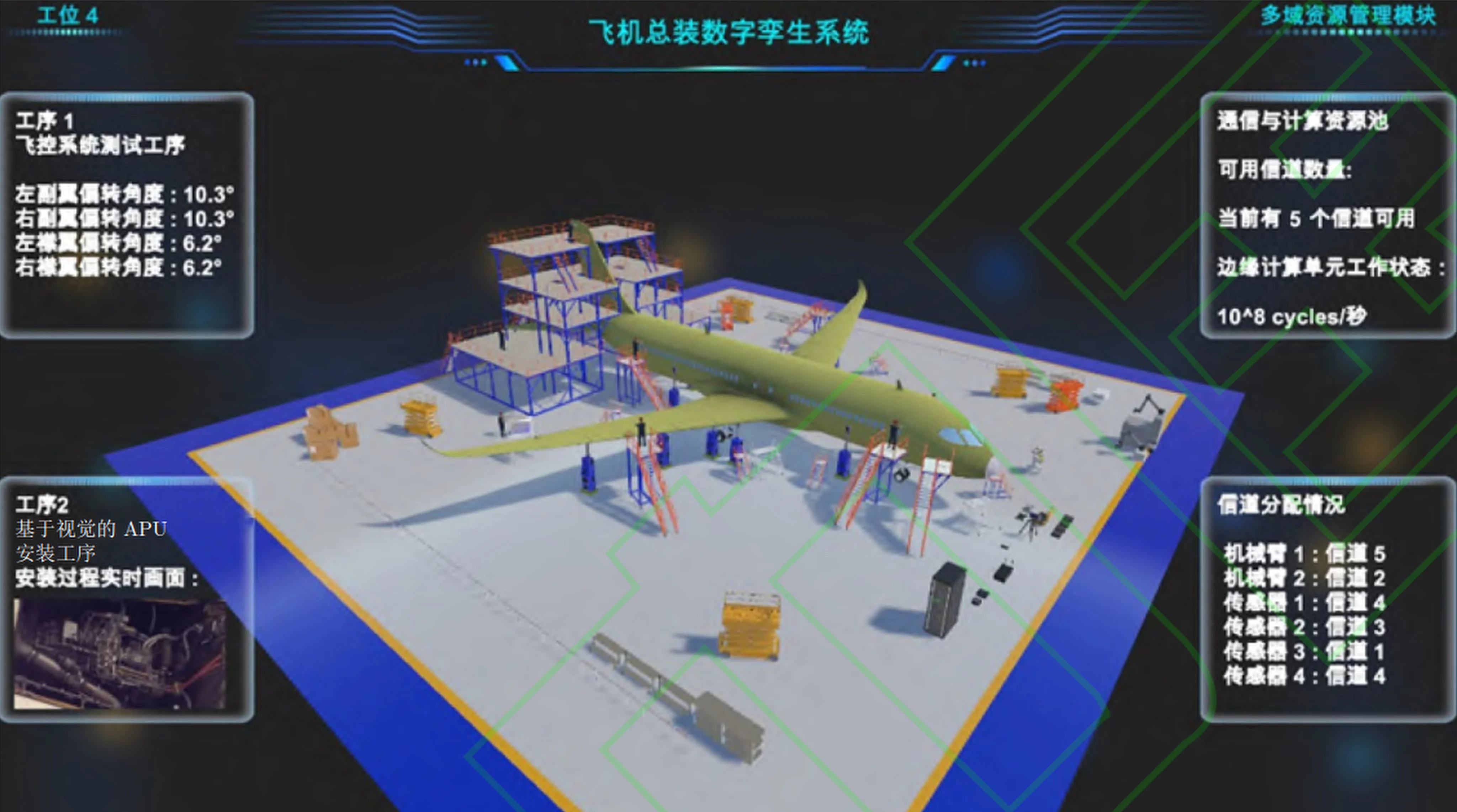

Their solution is high-fidelity digital twin technology. A virtual replica of the aircraft and its assembly environment is continuously updated with live data from the production floor.

As workers assemble the plane, their actions are mirrored in the digital twin. Cameras and motion sensors track their movements and tool usage, while wireless sensors such as angle sensors, gyroscopes and laser rangefinders monitor the plane's conditions.

This not only reduces quality issues but also speeds up the assembly process significantly, according to the researchers.

For example, when testing flight control systems, the digital twin compares the pilot’s input in the cockpit with the actual movement of the ailerons or elevators.

Any mismatch – say, a surface that does not respond correctly – is instantly flagged, allowing engineers to diagnose and fix issues before they cause a serious delay.

Moreover, the 5G network supports real-time video analytics from hundreds of cameras around the factory. AI algorithms scan footage for unsafe behaviours, such as unsecured equipment or improper protective gear, and alert supervisors instantly.

Looking ahead, the research team said they were integrating more AI-driven optimisation into the network.

“The deep integration of industrial networks and AI large models could lead to a new paradigm of knowledge-driven autonomous collaborative optimisation,” the team wrote.

“With the continuous advancement of China’s large aircraft strategy, the civil aviation industry is accelerating its transition into a new stage of independent and controllable high-quality development.

“The C919 embodies not only cutting-edge technologies such as advanced manufacturing, intelligent assembly and networked collaboration but also represents a significant leap forward in China’s capabilities for integrating complex systems and managing large-scale engineering projects,” they added.

China’s civil aviation industry is still in its infancy. Only about 50 C919 jets are expected to be produced this year, while Boeing delivered 348 commercial aircraft in 2024.