By Ettech Last Updated

Copyright indiatimes

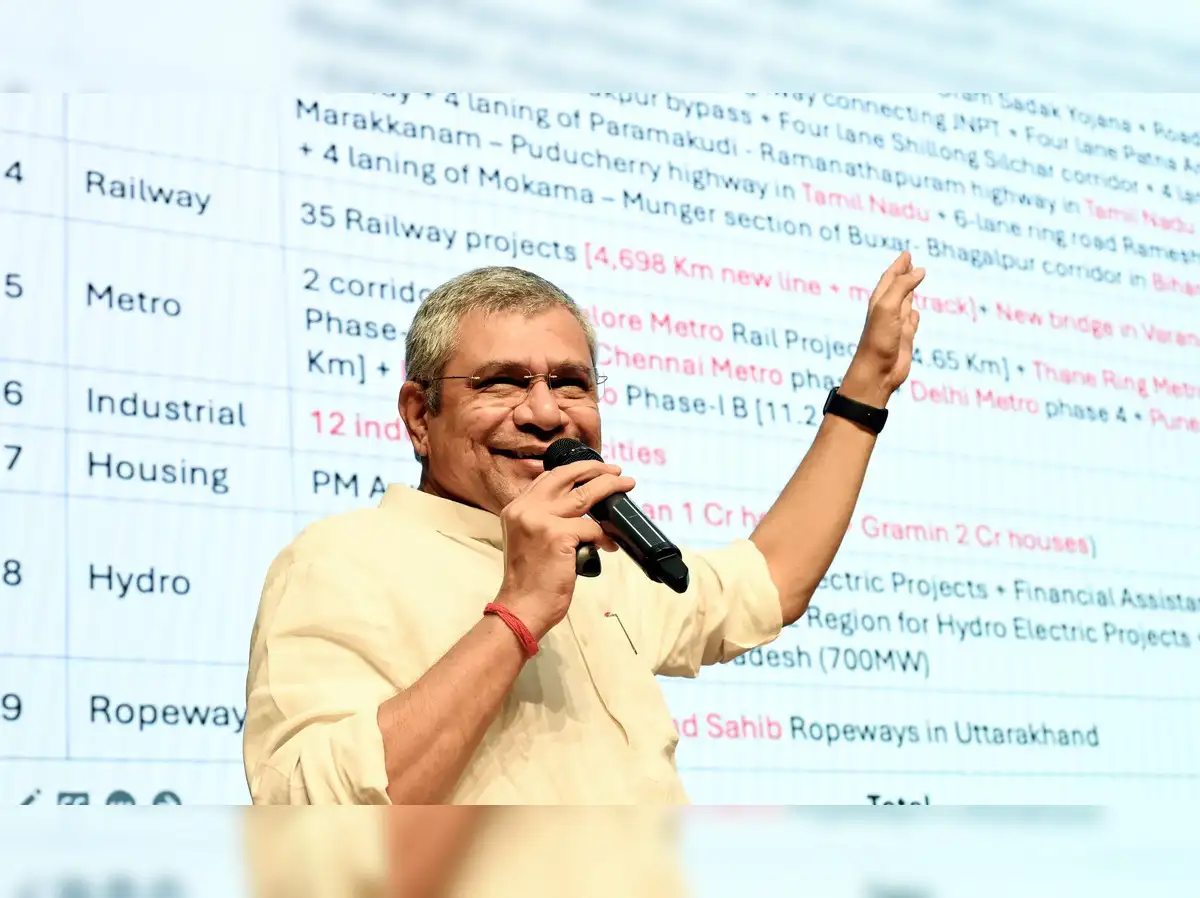

British semiconductor company Arm’s new Bengaluru facility will focus on designing cutting-edge chips, including advanced two-nanometre (2nm) nodes, union electronics and IT minister Ashwini Vaishnaw told reporters in Bengaluru on Tuesday.This will make “India a critical site for advanced semiconductor R&D,” he said.Smaller chips are more advanced, denser, faster and more power-efficient than bigger ones.Vaishnaw said Arm’s 2nm chip design programme would make it only the second such company after Renesas to achieve this benchmark in India, while indicating more advanced projects are in the pipeline.In May this year, the minister had inaugurated two new design facilities of Renesas Electronics India, located in Noida and Bengaluru. He had then said it would be India’s first design centre to work on cutting-edge 3nm chip design. “Designing at 3nm is truly next-generation. We’ve done 7nm and 5nm earlier, but this marks a new frontier,” he had said.Arm inaugurated its new Bengaluru office on Tuesday. Its chips power several mobile devices and servers worldwide.Asked about whether Dutch multinational corporation ASML – the world’s sole supplier of extreme UV photolithography machines, critical for producing advanced microchips – will set up shop in India, Vaishnaw noted that ASML officials came in good numbers to Semicon India 2025.”Their CEO was present. He met with us. He had a round table with the prime minister and their interest in India is very serious and we are continuously engaged with them,” he said.“We are also engaged with some real good technology developers like IMEC and IBM Albany,” he added.The minister said India started semiconductor production with the mature 28nm node “because that’s the beginning.”“But, over a period of time, once we develop the ecosystem in our country, we must go to more leading nodes and that process, the conceptual level we already have set now and now we have to work towards first making the first fab successful and then we move towards smaller nodes,” he explained.The government aims to make India a “product nation,” starting with 25 strategic chipsets for domestic and global markets, all with intellectual property rooted in India, he said.“We are beginning with about 25 chipsets, which start from very low complexity, high volume chips to high complexity but low volume chips,” Vaishnaw said, adding that a technical committee headed by the principal scientific advisor to the prime minister selected these chipsets.“We are working towards developing those chips where the IP rights, the entire chip design, the entire process is within a country,” he said.Vaishnaw said India’s ambition is to develop the complete semiconductor stack—including design, manufacturing, equipment, materials, and talent. He pointed to growing investments in chemicals, substrates, and other ecosystem pillars, supported by initiatives such as the $1-billion India Deep Tech Alliance fund, now prioritising semiconductors, AI, biotech, and other frontier technologies.He said the second phase of the India Semiconductor Mission (ISM 2.0) will focus on equipment and materials alongside fabs and ATMP to make “the ecosystem sustainable for the long run.”“The broad contours will be fundamentally on the entire ecosystem,” the minister said. “Time has come when we should be focusing more on the equipment and the materials because once they start getting manufactured here, then it becomes a very sustainable way forward. So, talent, design, fab, ATMP, the equipment which goes into manufacturing, chips, the materials, then the entire chemicals and gases and many other things. It’s a very complex ecosystem,” he explained.Asked about the outlay for ISM 2.0, Vaishnaw said he would reveal it “once it gets approved.”He said the government is working to ensure supply of rare earth elements and critical minerals. “Recently, the union cabinet approved the critical minerals mission, and we are working with people who understand the processing of rare earths because India has very good deposits of rare earth beach sands and we must develop our processing technologies,” he said. “That’s the next goal that we are working on and I think we will be able to do that in a very reasonable way.” The government also plans to modernise state-owned chip fab Semiconductor Lab (SCL) Mohali into a facility for both commercial production and as a resource for student and startup chip designers to tape out their products.“The modernisation process is progressing very well,” the minister said. “It is a very interesting structure that we have decided for SCL. One, we want to increase the production there. Second, we want to modernise all the equipment and manufacturing ecosystem that we have there. Three, we want to have SCL also to remain as one of the units where students who design or the startups who design chips get an opportunity to tape out their product and validate the product.”Going to a well-established fab in Taiwan or South Korea to validate their product may not be viable for students, researchers and startups because “you will require a minimum volume of production,” he explained.He noted that all the 28 student-designed chips that have been taped out recently were done at Mohali. So, SCL modernisation will help in “all the three things – increasing production, improving or modernising the equipment, and also retaining the characteristic of a research lab where the chips can be taped out,” Vaishnaw said.