Researchers at MIT have developed a method to interpret faint acoustic signals from lithium-ion batteries, opening the door to safer and longer-lasting energy storage.

The study links specific sound patterns to internal degradation processes, offering a low-cost way to monitor battery health in electric vehicles and grid-scale systems.

Linking sounds to degradation

The team from MIT’s Department of Chemical Engineering analyzed the subtle noises batteries make as they charge and discharge.

They found clear correlations between acoustic signatures and processes like gas generation or fracturing of electrode materials.

“In this study, through some careful scientific work, our team has managed to decode the acoustic emissions,” says Martin Z. Bazant, Chevron Professor of Chemical Engineering and professor of mathematics.

“We were able to classify them as coming from gas bubbles that are generated by side reactions, or by fractures from the expansion and contraction of the active material, and to find signatures of those signals even in noisy data.”

Graduate student Yash Samantaray adds that the approach allows investigation without damaging cells.

“I think the core of this work is to look at a way to investigate internal battery mechanisms while they’re still charging and discharging, and to do this nondestructively,” he says.

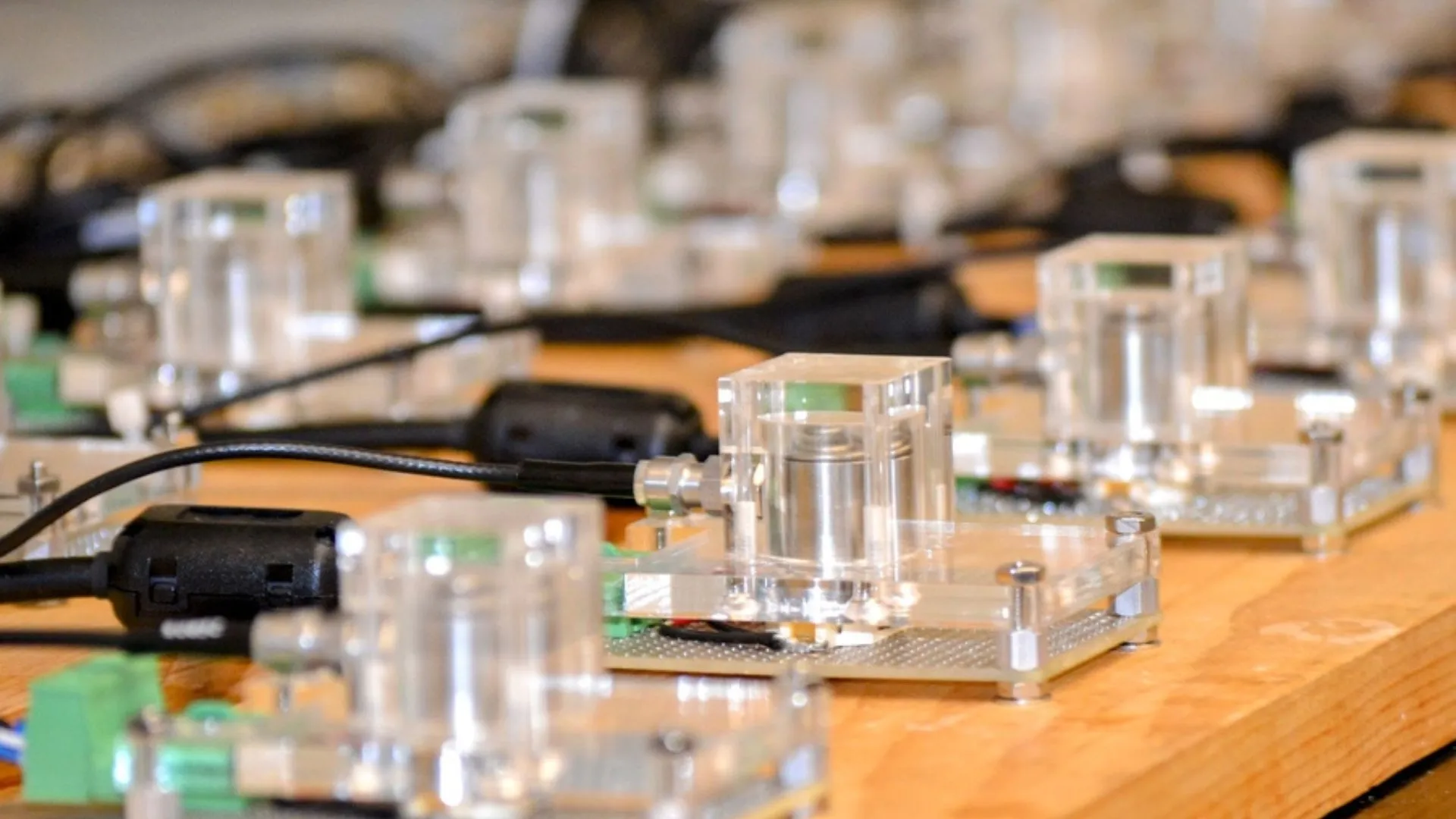

The researchers coupled electrochemical testing with acoustic recordings under real-world conditions.

They could pinpoint when certain emissions occurred by pairing voltage and current readings with sound patterns. After testing, they confirmed the results by examining cells under an electron microscope.

Toward real-world monitoring

Earlier attempts relied on crude thresholds, logging sound levels when they rose above a certain point. MIT’s team went further, using wavelet transforms to separate distinct signals from background noise. “No one had done that before,” Bazant says.

The method echoes how engineers track structural health in bridges. It offers an additional “window” beyond voltage and current in batteries. Bazant notes that it can reveal remaining useful life and even safety risks.

In related work with Oak Ridge National Laboratory, the team showed acoustic data could warn of thermal runaway before it triggered fires.

Samantaray sees immediate applications for material research. Lab groups could detect gas generation or particle fracturing without disassembling cells.

Bazant highlights value in manufacturing, where early detection of faulty cells could cut costs during formation cycling.

“By sensing them, it may be easier to isolate well-formed cells from poorly formed cells very early, even before the useful life of the battery, when it’s being made,” he says.

The group is already working with Tata Motors on a monitoring system for electric vehicles. They say the knowledge could help the industry build cheaper and safer diagnostic tools.

The study, published September 5 in Joule, was led by Samantaray and Alexander Cohen, along with former MIT research scientist Daniel Cogswell and Bazant.

It received support from the Toyota Research Institute, the Center for Battery Sustainability, the National Science Foundation, and the Department of Defense.