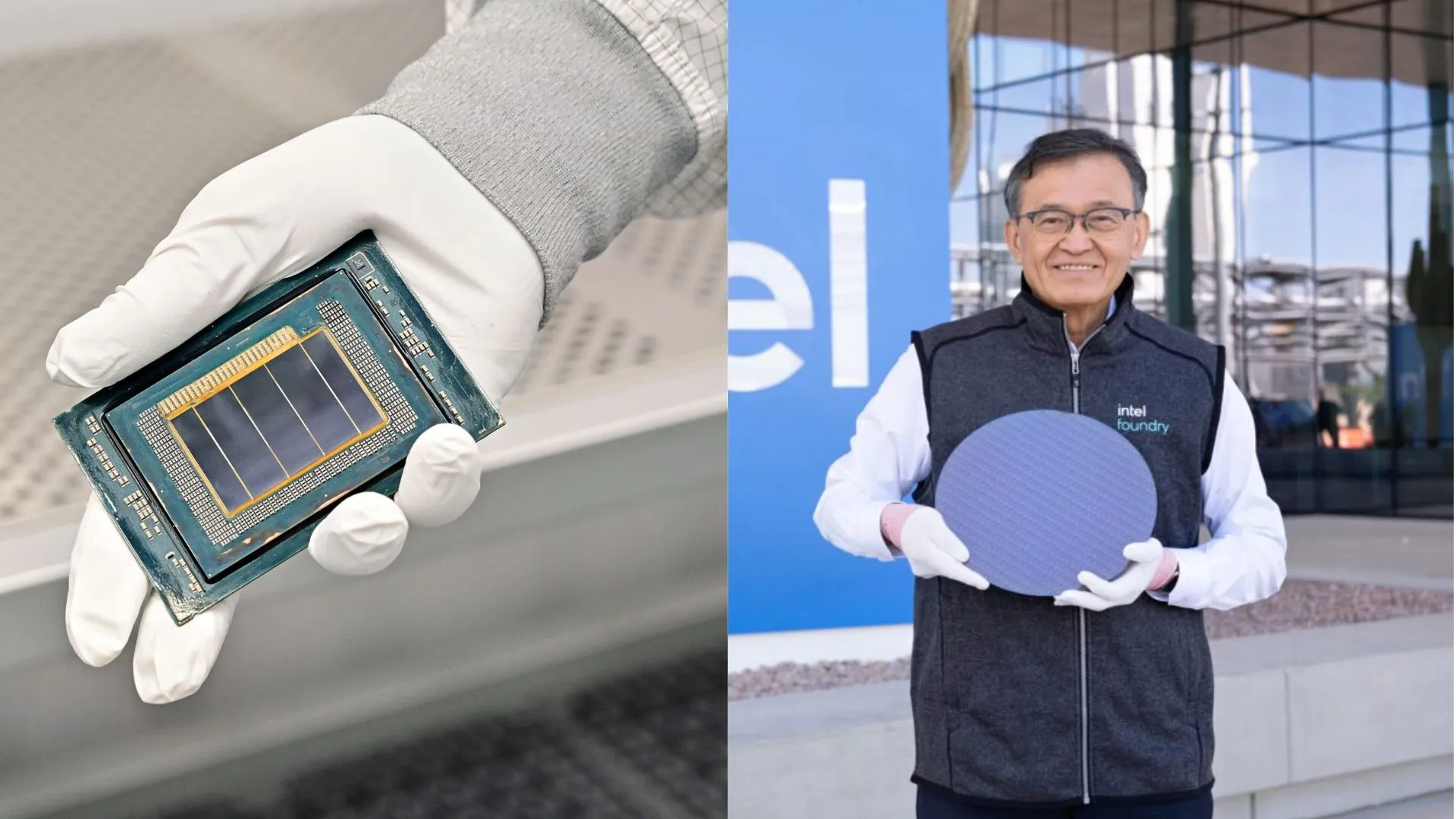

Intel has unveiled its most advanced client and server processors yet, marking a major leap in semiconductor technology.

The new Intel Core Ultra series 3 and Xeon 6+ chips promise higher performance, energy efficiency, and AI capabilities, all built on Intel’s groundbreaking 18A process.

Panther Lake, the codename for Intel Core Ultra series 3, is set to power consumer and commercial AI PCs, gaming devices, and edge solutions. It will begin high-volume production this year, with the first units shipping before the end of 2025.

“We are entering an exciting new era of computing, made possible by great leaps forward in semiconductor technology that will shape the future for decades to come,” said Intel CEO Lip-Bu Tan.

“Our next-gen compute platforms, combined with our leading-edge process technology, manufacturing and advanced packaging capabilities, are catalysts for innovation across our business as we build a new Intel.”

Panther Lake features a scalable, multi-chiplet architecture offering partners flexibility across form factors, segments, and price points.

Highlights include up to 16 new performance-cores (P-cores) and efficient-cores (E-cores) delivering more than 50% faster CPU performance than the previous generation.

A new Intel® Arc™ GPU with up to 12 Xe cores promises 50% faster graphics performance, while balanced XPU design delivers up to 180 TOPS for AI acceleration.

Scalable AI and robotics

Panther Lake’s reach goes beyond PCs. Intel is also targeting edge applications, including robotics, through a new Intel Robotics AI software suite and reference board. This allows customers to innovate with sophisticated AI capabilities for robot controls and perception.

Clearwater Forest, Intel’s codename for Xeon 6+, is the company’s first Intel 18A-based server processor and will launch in the first half of 2026.

Tailored for hyperscale data centers, cloud providers, and telcos, Xeon 6+ features up to 288 E-cores and a 17% uplift in Instructions Per Cycle (IPC) over the prior generation.

“The United States has always been home to Intel’s most advanced R&D, product design and manufacturing – and we are proud to build on this legacy as we expand our domestic operations and bring new innovations to the market,” Tan said.

Intel 18A: U.S. technology leader

Intel 18A, the first 2-nanometer class node developed and manufactured in the United States, delivers up to 15% better performance per watt and 30% improved chip density compared to Intel 3.

Keney innovations include RibbonFET, a new transistor architecture enabling efficient scaling, and PowerVia, a backside power delivery system enhancing energy flow.

Foveros 3D chip stacking technology enables flexible integration of multiple chiplets, forming advanced system-on-chip designs for both client and server applications.

Panther Lake and Xeon 6+, along with multiple future generations, will leverage Intel 18A and advanced packaging.

Fab 52: U.S. foundry milestone

Both chips are being manufactured at Intel’s state-of-the-art Fab 52 in Chandler, Arizona, part of Intel’s $100 billion investment to expand domestic operations.

The facility strengthens U.S. manufacturing leadership, supports a resilient semiconductor supply chain, and positions Intel to serve both its own product lines and foundry customers.

Fab 52 builds on Intel’s 56 years of R&D and manufacturing advancements in Oregon, Arizona, and New Mexico.